4 Main Types of Hoppers and Their Uses

If you work in a warehouse or manufacturing, you understand the challenges of moving materials, products, and waste efficiently.

Nothing slows down the manufacturing process more than having a workspace cluttered with trash, unfinished products, or unnecessary parts. And ideally you don't want to move these things around more than you need to, because moving them necessarily wastes time.

At Iron Bull Manufacturing, we understand why you might have issues with this. We have experienced it ourselves! We've found a solution that helps solve these issues:

Trash hoppers!

Trash hoppers allow a manufacturing facility to efficiently store and move trash, scrap parts, materials, and products.

Not only does this increase a facility’s efficiency, but it also makes a plant floor cleaner, easier, and safer to maneuver.

There are many types of hoppers available, and choosing the correct one usually depends on your specific needs.

In this article, we will look at four of the main types of hoppers, how they are used, and their unique designs. We will also take a brief look at how hoppers work.

Are you ready to learn which hopper is right for your business?

Let’s get started!

1. How Do Hoppers Work?

All trash hoppers (also known as forklift dumpsters) are designed for the same purpose - collecting scrap materials in a large bin for easy storage, transportation, or disposal.

This efficient collection of waste or materials in hoppers creates multiple benefits in the workplace, including:

- Less clutter and waste material on the floor

- Streamlined scrap collection and removal

- Safer workspace due to correct scrap material storage

- Increased efficiency overall in the manufacturing process

- Happier employees due to an organized and clutter-free workspace

There are different styles of self-dumping hoppers, and each style is designed for a specific use. For example, a self-dumping hopper is made for misc scrap and needs an open top, but a sawdust hopper needs to be fully enclosed to capture all the sawdust.

Hoppers used in manufacturing settings are usually made from steel or a similar material. The hopper size, gauge of metal used, and overall design are usually specific to the materials being stored or transported.

So how do you know what size hopper or which metal gauge you need?

These answers depend on the materials and use of the hopper.

If you are using a self-dumping hopper for scrap wood in a truss shop, your hopper doesn't need to be as robust as it would if you were using it for scrap metal in a metal shop. However, the truss shop may need a larger hopper if their wood scrap pieces are several feet in length.

Each business needs to look at its machinery, scrap products, and available space to determine which hopper style and size works best for them.

Most hoppers are designed with built-in fork pockets for easy movement with a forklift or pallet jack. Depending on the size and weight capacity, casters can also be used for quick movement.

2. Self-Dumping Hoppers

Self-dumping hoppers are designed to dump materials without needing an external motor or pulley.

Self-dumping hoppers have a release latch when the hopper is ready to be dumped and emptied. Releasing the latch allows the hopper to begin unloading the materials from the side, and when the load is dumped, the hopper closes, and the release latch becomes locked.

What makes self-dumping hoppers truly efficient?

They allow a manufacturing plant to easily dump scrap materials, trash, or scrap without needing additional motors or pulleys.

Instead, all you need is a forklift to lift the hopper over a dumpster or truck, release the latch, and let it dump! No extra motion, no extra machinery to get broken.

Self-dumping hoppers are ideal when working with waste or recycling. When used as a trash hopper, many metal or wood shops find it efficient to place the trash hopper under their saws or other equipment. Then the pieces of scrap fall directly into the trash hopper for easy recycling or disposal.

Click here to learn more about Self-Dumping Hoppers!

3. Stretch Hoppers

Like self-dumping hoppers, stretch hoppers are designed for easy movement and dumping with a forklift.

The main difference with stretch hoppers is their design.

Instead of being used for small scrap pieces or products, stretch hoppers are made for long pieces of scrap or material.

Depending on the length of your scrap, stretch hoppers are built with either both ends or one end left open so long pieces of scrap can stick out the ends. This allows the hopper to be easily used for long and medium pieces without requiring a large footprint.

Where are stretch hoppers effective?

If you have a truss shop and cut long pieces of lumber, you might have wood scrap 4-6 feet or longer.

Instead of needing an enclosed hopper that is 6 feet wide, which would take up a lot of space in your shop, you can get a smaller stretch hopper and keep the ends open. The smaller stretch hopper will require less space and be just as effective, if not easier to use.

Stretch hoppers are also used to haul long products and materials efficiently. If several pieces of long metal need to be moved, a stretch hopper does this quickly and safely.

Click here to learn more about Stretch Hoppers!

4. Drop Bottom Hoppers

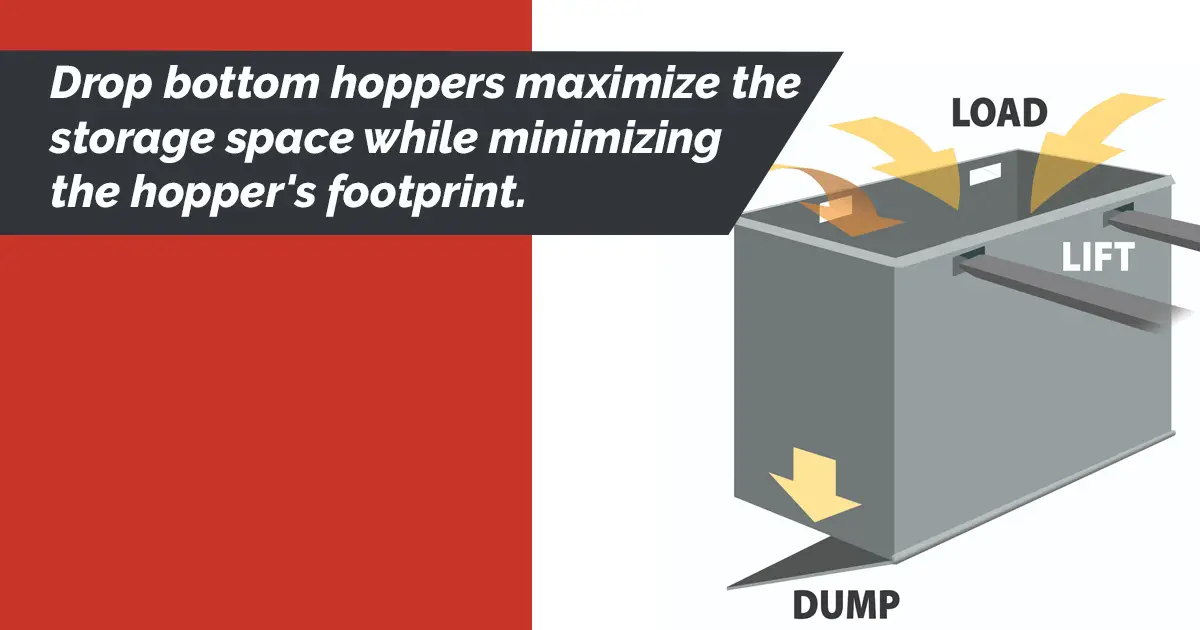

Drop bottom hoppers, also known as bottom dump hoppers, are designed to minimize the hopper’s footprint while maximizing the storage space. That means their design and features are different from a regular self-dumping hopper.

How is a drop bottom hopper different?

First, the forklift inserts are usually at the top of the hopper instead of the bottom.

Second, the hopper dumps materials when the bottom is either opened or “dropped.” It does not dump out the side like a self-dumping hopper. It dumps out the bottom, through a trapdoor.

Third, drop bottom hoppers are built to maximize every part of the hopper. Instead of needing room for a dumping mechanism, a bottom dump hopper uses every cubic inch of available space for scrap.

Where are drop bottom hoppers most effective?

They work well as trash hoppers when space is a concern. If you have limited space, or a tight corner, drop bottom hoppers work well to maximize the area you have. They don't waste a bit of space in order to help you maximize all the space you have.

Click here to learn more about Drop Bottom Hoppers!

5. Sawdust Hoppers

Everyone who works with wood knows how many issues sawdust can create.

Difficulty breathing, dust and dirt everywhere, difficult cleanup, and other issues are quickly noticeable.

Sawdust hoppers solve the sawdust issue by capturing the sawdust in an enclosed hopper. A forklift then takes the hopper to the sawdust collection area, and the sawdust is dumped from the bottom.

To minimize dust and dirt, sawdust hoppers typically come with an inlet port that can be securely connected to a dust and sawdust collector or fan. That way you don't have as much sawdust floating around in the air.

Click here to learn more about Sawdust Hoppers!

6. Conclusion

No matter your industry or what you manufacture, you always have to deal with trash, scrap, and unused product.

The key is managing these elements efficiently and safely.

With their many designs and uses, you can purchase a trash hopper for your plant and make your team and plant safer, cleaner, and more efficient!

At Iron Bull Manufacturing, we develop many different sizes, styles, and grades of hoppers. From self-dumping hoppers, to sawdust hoppers, to forklift dumpsters, to drop bottom hoppers, along with specialty hoppers, we have the design you need.

Contact us today to get your custom quote for your new hopper!

Iron Bull Manufacturing first began serving its customers in 1994 when Crist King started a farm machinery shop in Lancaster, PA. In 2002, the King family moved to their present location in Marshall, IN.

Because the machine business was “feast or famine” depending on the time of year and corresponding farm work, the company decided to branch into creating self-dumping hoppers.

They had some experience repairing hoppers and dumpsters, but they wanted to create their own line of quality hoppers that they could manufacture and sell. To help them start this hopper line, Joe Glick joined the company. Joe had experience with metal manufacturing after starting and selling his own manufacturing business.

Creating a new product line of self-dumping hoppers was not easy. It required research, making prints, building custom jigs and equipment, and significant time in development.

The name “Iron Bull” was chosen to reflect what the company wanted for every customer experience: Quality products that are tough and strong.

After doing some custom work on tractor canopies, Iron Bull began its line of tractor canopies and frames in 2015. Like the hoppers, this initially required a lot of research and new equipment.

With the emphasis being on safety, Iron Bull worked hard to have their tractor equipment ROPS certified. Today Iron Bull is proud to offer ROPS certified tractor frames and canopies that look like the original tractor parts.

Today, Iron Bull continues to live up to its name by creating well-built products that are safe, strong, and efficient.

They continue to work hard to listen to their customers, to continue their research and learning, and to continue getting better at serving their customers by creating quality self-dumping hoppers and tractor canopies and ROPS equipment.

Contact us today to have your expectations exceeded by the Iron Bull Manufacturing experience!

Thank you for visiting us! If you have any questions, don’t hesitate to ask.

“I’ve been worrying about my grandson mowing with the tractor. We decided a couple thousand dollars is money well spent to keep him safe”

- A caring Grandpa