“My guys say they like the Iron Bull hoppers better than what we had bought before. They say they are built better and are easier to dump.”

- Tom Saari, Pallet Resource

How we've helped other shops

0+

HoppersIn Use

A few of the companies that use our hoppers

Popular Quick Ship Hoppers Available Now

- Available in 1/2, 1, and 2-yard models

- Tiered & competitive pricing when buying in bulk

- In stock and ship within 4 business days

- Ideal for general plant maintenance, lightweight recycling, light wood and metal scraps, etc.

Click one of our quick-ship hoppers below to view more photos, see full specs, or pruchase.

Standard Self Dumping Hoppers

- Available in 2000 lb, 4000 lb, and 6000 lb capacities

- Sizes range from ¼ yard to 5 yard capacity

- 2000 lb capacity: ideal for general plant maintenance, lightweight recycling, cardboard, light wood and metal scraps, etc

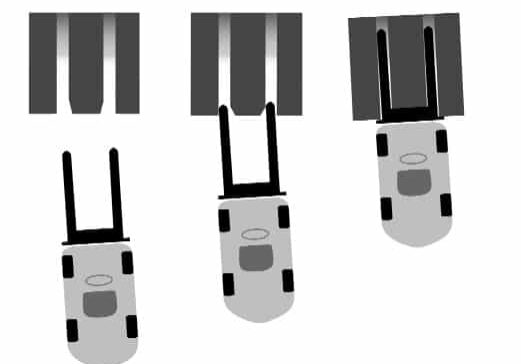

- Open style base (full-length channel base upgrade available)

- Pinless rocker for a smoother dump

- 4000 lb and 6000 lb capacity: ideal for heavier wood and metal scraps, scrapyard industry applications, etc.

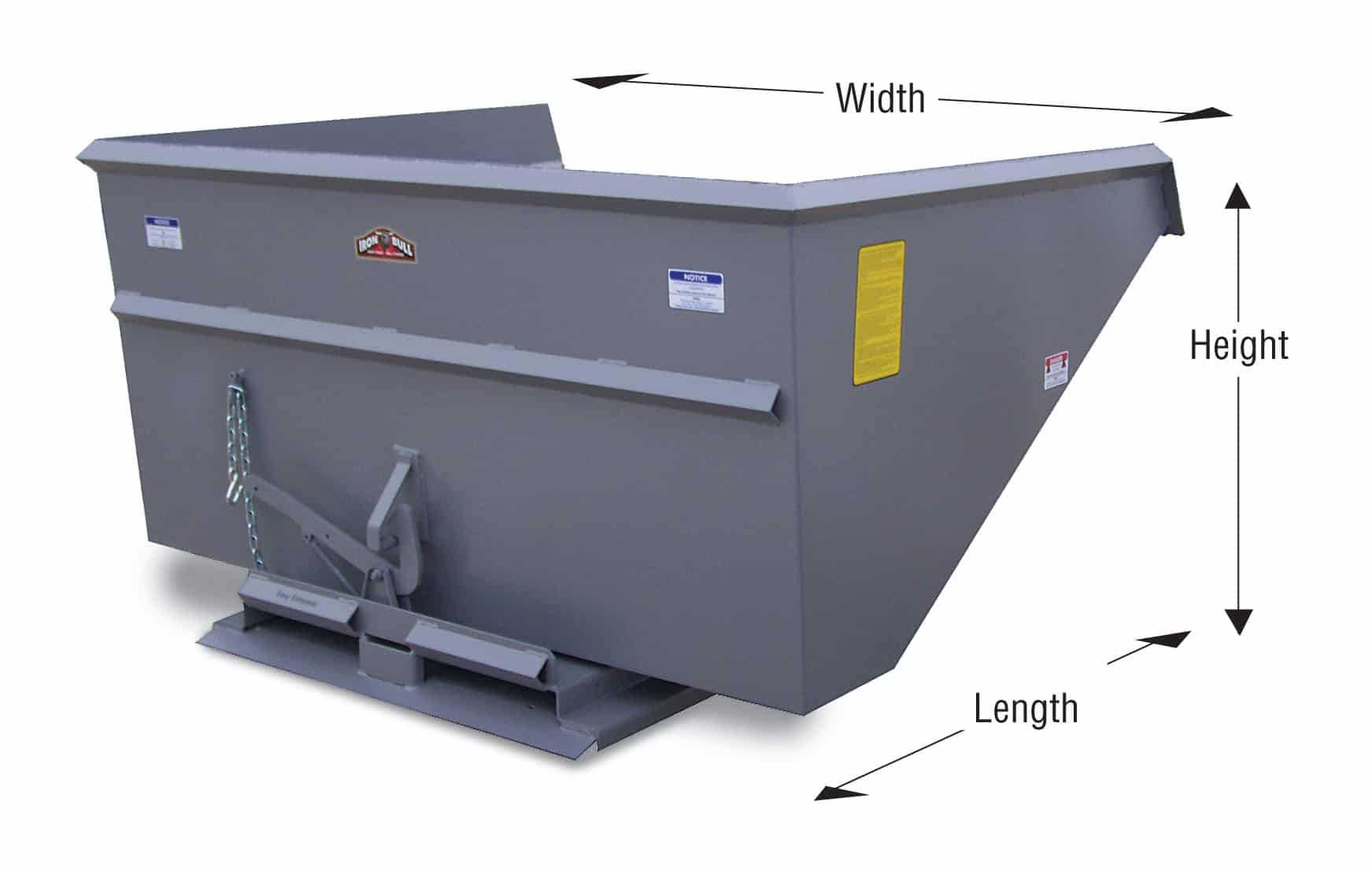

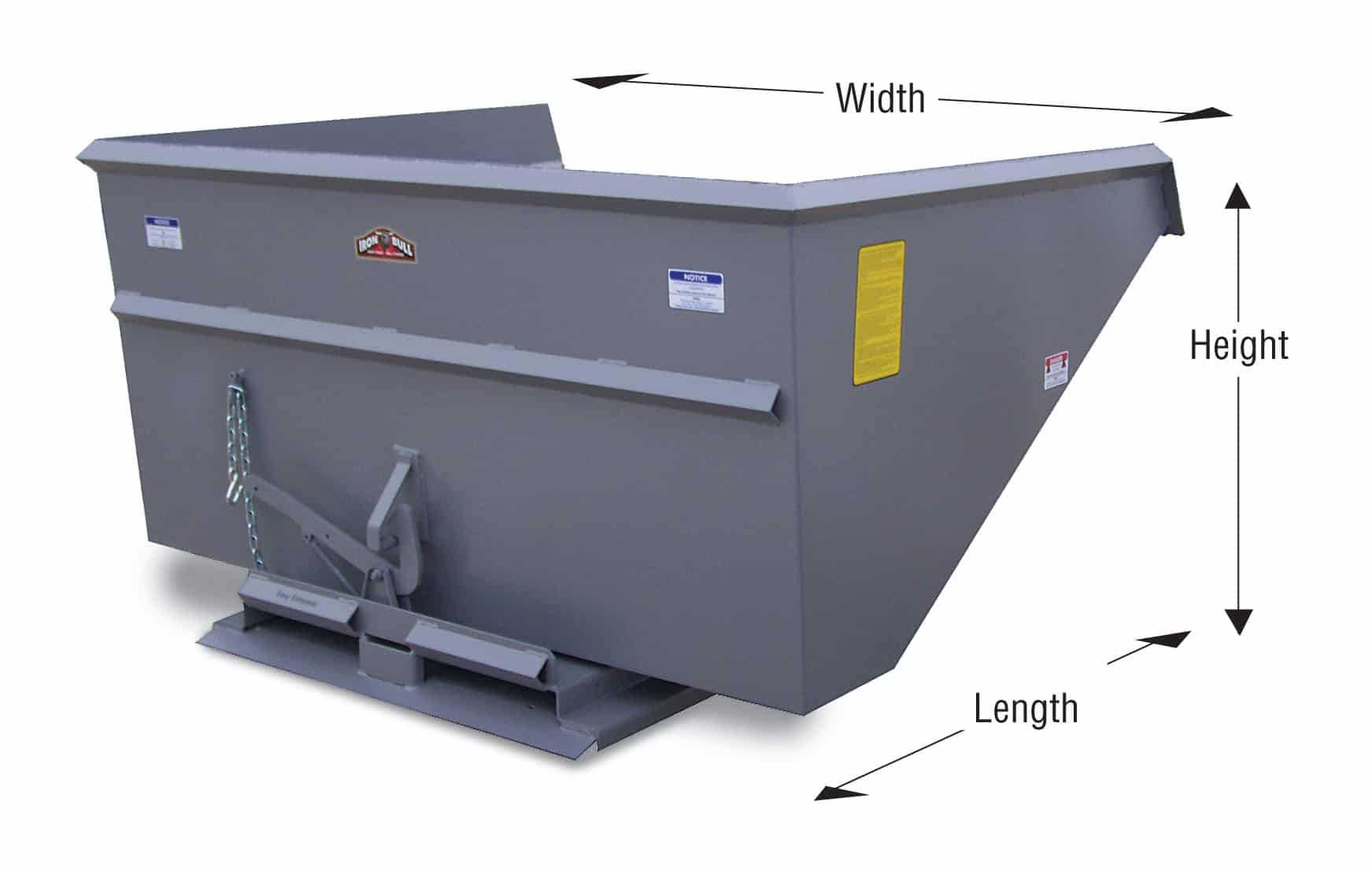

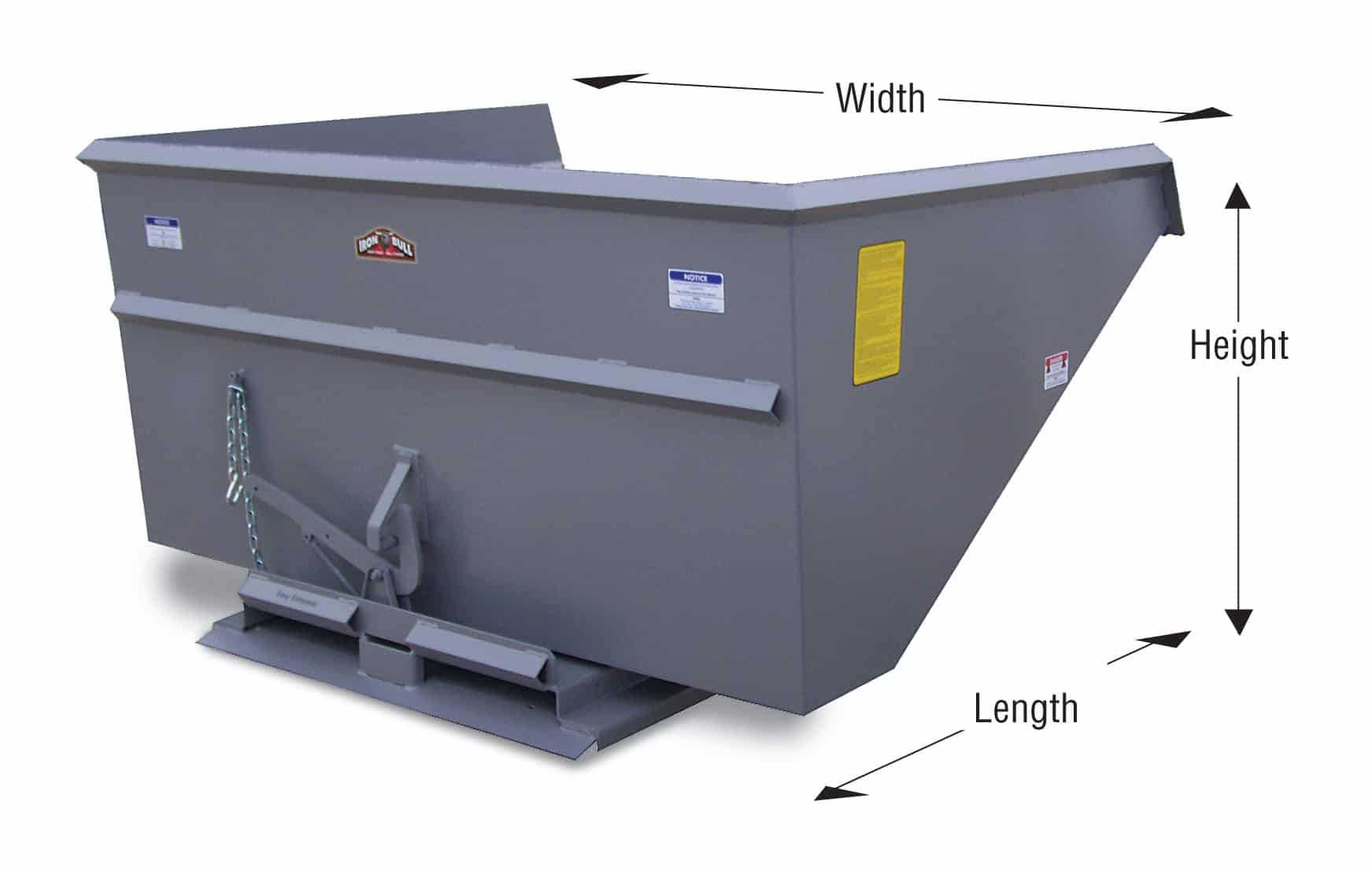

Choose The Self Dumping Hopper That's Right For You

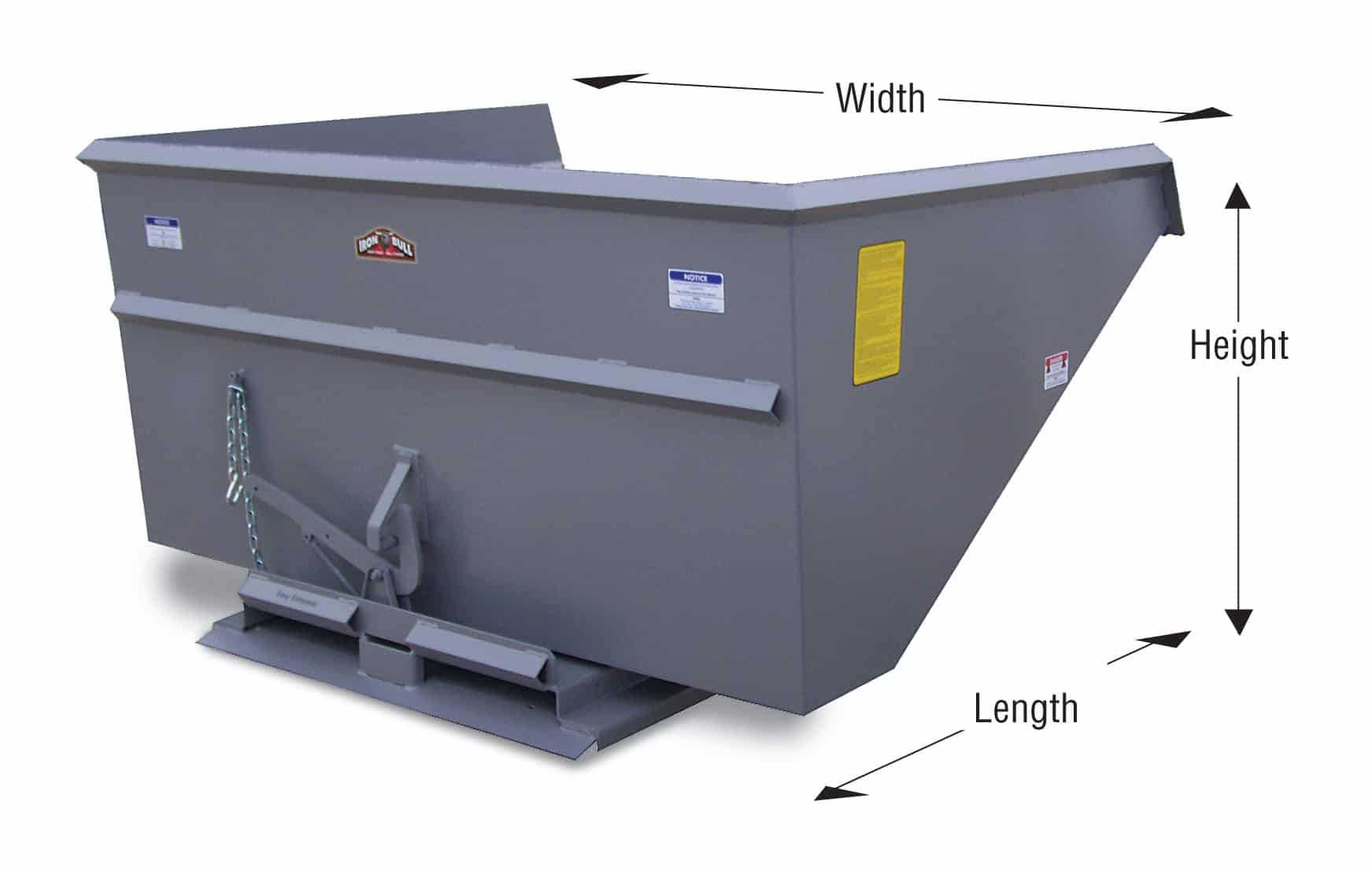

Note: each hopper within a particular series has the same height and length. Only the width varies to handle the different capacities. For instance, the Brahma Bull 4yd and the Brahma Bull 6yd are both 60” high and 90” long. Only the width is different. Use the following chart to help you choose the cubic size you need.

Note: Hopper models highlighted in yellow are popular models typically available for quick shipping. Click here for more details.

Mini Bull Series

Smaller Hoppers

Overall Length 38"

Overall Height 23.75"

Ideal for narrow or tight spaces

Dimensions may vary slightly

| Yard Cap. | Width |

|---|---|

| 1/8 yard | 22" |

| 1/4 yard | 30" |

| 3/8 yard | 42" |

2000 lb. capacity

12 ga hopper - 7 ga open style base

| WGT | Item # |

|---|---|

| 255 lb | 125M02 |

| 281 lb | 025M02 |

| 308 lb | 375M02 |

4000 lb. capacity

Coming Soon...

| WGT | Item # |

|---|---|

| N/A | N/A |

| N/A | N/A |

| N/A | N/A |

6000 lb. capacity

7 ga hopper - 7 ga open style base

| WGT | Item # |

|---|---|

| 296 lb | 125M06 |

| 340 lb | 025M06 |

| 386 lb | 375M06 |

Baby Bull Series

Smaller Hoppers

Overall Length 50"

Overall Height 27"

Use beside your lathe, drill press, table saw, etc.

Dimensions may vary slightly

| Yard Cap. | Width |

|---|---|

| 1/4 yard | 22" |

| 1/3 yard | 25" |

| 1/2 yard | 37" |

| 3/4 yard | 55" |

2000 lb. capacity

12 ga hopper - 7 ga open style base

| WGT | Item # |

|---|---|

| 230 lb | 025A02 |

| 250 lb | 333A02 |

| 300 lb | 050A02 |

| 360 lb | 075A02 |

4000 lb. capacity

Coming Soon...

| WGT | Item # |

|---|---|

| N/A | N/A |

| N/A | N/A |

| 376 lb | 050A04 |

| 466 lb | 075A04 |

6000 lb. capacity

7 ga hopper - 1/4" open style base

| WGT | Item # |

|---|---|

| 300 lb | 025A06 |

| 354 lb | 333A06 |

| 452 lb | 050A06 |

| 572 lb | 075A06 |

Junior Bull Series

Medium Size Hoppers

Overall Length 66"

Overall Height 34"

Good for those not-so-tight spaces but that still won't take a Big Bull.

Dimensions may vary slightly

| Yard Cap. | Width |

|---|---|

| 3/4 yard | 33" |

| 1 yard | 43" |

| 1 1/4 yard | 53" |

| 1 1/2 yard | 63" |

2000 lb. capacity

12 ga hopper - 7 ga open style base

| WGT | Item # |

|---|---|

| 403 lb | 075J02 |

| 457 lb | 100J02 |

| 491 lb | 125J02 |

| 561 lb | 150J02 |

4000 lb. capacity

Coming Soon...

| WGT | Item # |

|---|---|

| 497 lb | 075J04 |

| 546 lb | 100J04 |

| 590 lb | 125J04 |

| 660 lb | 150J04 |

6000 lb. capacity

7 ga hopper - 1/4" open style base

| WGT | Item # |

|---|---|

| 590 lb | 075J06 |

| 635 lb | 100J06 |

| 689 lb | 125J06 |

| 759 lb | 150J06 |

Big Bull Series

Larger Hoppers

Overall Length 72"

Overall Height 41.5"

Our most popular hopper. These hoppers hold a lot of material!

Dimensions may vary slightly

| Yard Cap. | Width |

|---|---|

| 1 1/2 yard | 46" |

| 2 yard | 58" |

| 2 1/2 yard | 72" |

| 3 yard | 86" |

2000 lb. capacity

12 ga hopper - 7 ga open style base

| WGT | Item # |

|---|---|

| 565 lb | 150G02 |

| 650 lb | 200G02 |

| 710 lb | 250G02 |

| 758 lb | 300G02 |

4000 lb. capacity

Coming Soon...

| WGT | Item # |

|---|---|

| 699 lb | 150G04 |

| 794 lb | 200G04 |

| 865 lb | 250G04 |

| 941 lb | 300G04 |

6000 lb. capacity

7 ga hopper - 1/4" open style base

| WGT | Item # |

|---|---|

| 832 lb | 150G06 |

| 938 lb | 200G06 |

| 1020 lb | 250G06 |

| 1124 lb | 300G06 |

Brahma Bull Series

Larger Hoppers

Overall Length 90"

Overall Height 60"

Ideal for construction sites. Make sure your skid steer or forktruck has the correct capacity to handle these when full.

Dimensions may vary slightly

| Yard Cap. | Width |

|---|---|

| 3 yard | 48" |

| 4 yard | 62" |

| 5 yard | 76" |

2000 lb. capacity

12 ga hopper - 7 ga open style base

| WGT | Item # |

|---|---|

| 997 lb | 300R02 |

| 1129 lb | 400R02 |

| 1212 lb | 500R02 |

Capacity chart for our Self Dumping Hoppers

Note: each self dumping hopper within a particular series has the same height and length. Only the width varies to handle the different capacities. For instance, the Brahma Bull 4yd and the Brahma Bull 6yd are both 60”high and 90”long. Only the width is different. Use the following chart to help you choose the cubic size you need.

The Mini Bull series has an ultra low profile and is short. The overall height is 26”and the length is 38”. Designed for narrow or tight areas. Available in 1/8 yd. increments.

Capacity: 1/8 (17”W), 1/4 (30”W), 3/8 (42”W)

“Stretch”Series Capacity: 1/2 (57”W), 5/8 (70”W), 3/4, (84”W), 7/8 (98”W), 1yd. (111”W)

The Baby Bull Series is also a low profile hopper. The overall height is 30” and the length is

50”. This series is very popular in the wood working industry. It is ideal for placing beside

your table saw, or, with the Bat-Wing™ Base, underneath your chop saw bench.

Capacity: 1/3 (25”W), 1/2 (37”W), 3/4 (55”W)

“Stretch”Series Capacity: 1 (73”W), 1 1/4 (90”W), 1 1/2yd. (102”W)

The Junior Bull series is a medium height hopper. The overall height is 36”and the length is 66”.

Capacity: 3/4 (33”W), 1 (43”W), 1 1/4 (53”W), 1 1/2 (63”W)

“Stretch”Series Capacity: 1 3/4 (73”W), 2yd. (83”W)

The Big Bull series is our most popular. Overall height is 43”and the length is 72”. Be sure your

forklift has the correct capacity to handle these when full.

Capacity: 1 1/2 (46”W), 2 (58”W), 2 1/2 (72”W), 3 (86”W)

“Stretch”Series Capacity: 3 1/2 (100”W), 4 yd. (114”W)

The Brahma Bull series’ overall height is 60”and the length is 90”. These hoppers hold lots of

material! Be sure your forklift has the correct capacity to handle these when full.

Capacity: 4 (62”W), 5 (76”W), 6 (90”W), 7 (104”W), 8 yd. (118”W)

How tough do you need your hopper?

Popular Options

| Item # | Item Description |

|---|---|

| DFS | Dump-From-Seat™ Retractable Latch Rope |

| APD | Automatic Push-and-Dump from seat |

| BAPD | Automatic Push-and-Dump from seat (for Standard Models) |

| PC4S2R2 | 2" x 4" Phenolic Casters (2 swivel & 2 rigid). For Mini and Baby Bull Hopper Models. Adds 4-1/4" in height. |

| PC6S2R2 | 2" x 6" Phenolic Casters (2 swivel & 2 rigid). For Jr. Bull and Big Bull hoppers. |

| PH | Push Handle (for use with casters) |

| HFL | Hopper Floor Lock |

Other Options

| Item # | Item Description |

|---|---|

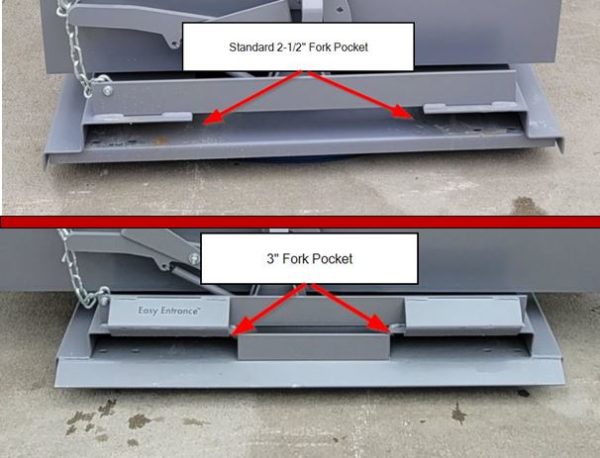

| 3FP | 3” Fork Pocket instead of 2-1/2” |

| 3WE | 3 way fork entry |

| CPE2 | Set of 2 crane Pick Up Eyes |

| FRO | Fluid Reclaim Option |

| QAO | Skid Steer Quick Attach option |

| SF | Stack Feature on Hoppers up to 58” wide |

| DHP | 1” Drain Hole with Plug |

| LIDS | Optional Lid to keep contents contained |

More information on popular self-dumping forklift hopper options:

Casters

A simple addition with a huge effect. Add ease of movement within your shop without using a forktruck, saving on propane and forklift wear and tear.

Automatic Dump-From-Seat™

A nylon leash extends or retracts as needed. The latch rope reel has a magnetic mounting clip, keeping the reel on the hopper when not in use. When in use, simply stick it to the forklift frame. To dump your trash hopper, just lock the thumb button and pull. After dumping, tilt the forklift mast back and the hopper will automatically roll back into its locked position again.

Automatic Push-and-Dump™ On Our Self Dumping Hoppers

The Automatic Push and Dump™ is designed for dumping into roll-offs or other large waste containers. By pushing the latch push tube gently against the edge of the large waste container, the hopper latch is released, dumping the scrap material quickly.

3" Fork Pockets

Have more space for thicker and heavy-duty fork attachments by upgrading from the standard 2-1/2" pockets to 3" fork pockets.

Fluid Reclaim Option

In sizes 1/8 yard to 2 yards, we can add a drainage hole at the bottom of your hopper. This allows you to drain liquid before dumping your hopper.

Skid Steer Quick Attach

Use a self-dumping hopper on your farm, construction site, and other off-road areas with a skid steer quick attachment. Available on hoppers 3.75' to 10' wide.

The Steps to Efficiency are:

Confirm: We confirm your hopper size and footprint before we ship your product.

Delivery: Our short lead times ensure that you receive your hopper quickly.

Enjoy: See increased efficiency, productivity, and regained space in your shop!

-

Confirm

We confirm your hopper size and footprint before we ship your product.

-

Delivery

Our short lead times ensure that you receive your hopper quickly.

-

Enjoy

Enjoy your increased efficiency, productivity, and regained space!

Deluxe Heavy Duty Self Dumping Hoppers

- Available in 2800 lb, 5000 lb, and 7000 lb capacities

- Sizes range from ¼ yard to 12 yard capacity

- 2800 lb capacity: ideal for scraps and general plant maintenance

- 5000 lb capacity: ideal for heavy scraps, dense trash, etc.

- 7000 lb capacity: ideal for heavy scrap, stone & aggregate materials, and other heavy industrial applications

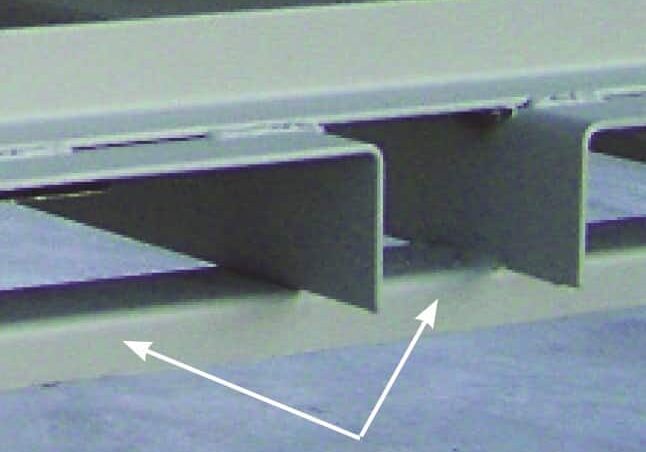

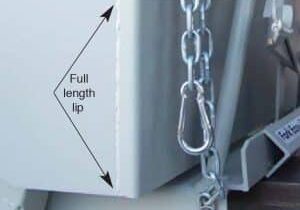

What makes our deluxe hoppers some of the strongest on the market?

Choose The Self Dumping Hopper That's Right For You

Note: each self dumping hopper within a particular series has the same height and length. Only the width varies to handle the different capacities. For instance, the Brahma Bull 4yd and the Brahma Bull 6yd are both 60”high and 90”long. Only the width is different. Use the following chart to help you choose the cubic size you need.

Baby Bull Series

Smaller Hoppers

Overall Length 50"

Overall Height 29"

Use beside your lathe, drill press, table saw, etc.

Dimensions may vary slightly

| Yard Cap. | Width |

|---|---|

| 1/4 yard | 22" |

| 1/3 yard | 25" |

| 1/2 yard | 37" |

| 3/4 yard | 55" |

Heavy Duty Standard

2800 lb. capacity

12 ga hopper - 7 ga full length channel base

| WGT | Item # |

|---|---|

| 250 lb | 025A28 |

| 281 lb | 333A28 |

| 349 lb | 050A28 |

| 433 lb | 075A28 |

Extra Heavy Duty

5000 lb. capacity

10 ga hopper - 7 ga full length channel base

| WGT | Item # |

|---|---|

| 270 lb | 025A05 |

| 308 lb | 333A05 |

| 384 lb | 050A05 |

| 480 lb | 075A05 |

Super Heavy Duty

7000 lb. capacity

7 ga hopper - 1/4" full length channel base

| WGT | Item # |

|---|---|

| 320 lb | 025A07 |

| 375 lb | 333A07 |

| 476 lb | 050A07 |

| 599 lb | 075A07 |

Junior Bull Series

Medium Size Hoppers

Overall Length 66"

Overall Height 36"

Good for those not-so-tight spaces but that still won't take a Big Bull.

Dimensions may vary slightly

| Yard Cap. | Width |

|---|---|

| 3/4 yard | 33" |

| 1 yard | 43" |

| 1 1/4 yard | 53" |

| 1 1/2 yard | 63" |

Heavy Duty Standard

2800 lb. capacity

12 ga hopper - 7 ga full length channel base

| WGT | Item # |

|---|---|

| 470 lb | 075J28 |

| 513 lb | 100J28 |

| 546 lb | 125J28 |

| 609 lb | 150J28 |

Extra Heavy Duty

5000 lb. capacity

10 ga hopper - 7 ga full length channel base

| WGT | Item # |

|---|---|

| 516 lb | 075J05 |

| 568 lb | 100J05 |

| 608 lb | 125J05 |

| 679 lb | 150J05 |

Super Heavy Duty

7000 lb. capacity

7 ga hopper - 1/4" full length channel base

| WGT | Item # |

|---|---|

| 653 lb | 075J07 |

| 731 lb | 100J07 |

| 788 lb | 125J07 |

| 861 lb | 150J07 |

Big Bull Series

Larger Hoppers

Overall Length 72"

Overall Height 43"

Our most popular hopper. These hoppers hold a lot of material!

Dimensions may vary slightly

| Yard Cap. | Width |

|---|---|

| 1 1/2 yard | 46" |

| 2 yard | 58" |

| 2 1/2 yard | 72" |

| 3 yard | 86" |

Heavy Duty Standard

2800 lb. capacity

12 ga hopper - 7 ga full length channel base

| WGT | Item # |

|---|---|

| 640 lb | 150G28 |

| 740 lb | 200G28 |

| 795 lb | 250G28 |

| 828 lb | 300G28 |

Extra Heavy Duty

5000 lb. capacity

10 ga hopper - 7 ga full length channel base

| WGT | Item # |

|---|---|

| 725 lb | 150G05 |

| 825 lb | 200G05 |

| 876 lb | 250G05 |

| 978 lb | 300G05 |

Super Heavy Duty

7000 lb. capacity

7 ga hopper - 1/4" full length channel base

| WGT | Item # |

|---|---|

| 935 lb | 150G07 |

| 1045 lb | 200G07 |

| 1130 lb | 250G07 |

| 1238 lb | 300G07 |

Brahma Bull Series

Larger Hoppers

Overall Length 90"

Overall Height 64.75"

Ideal for construction sites. Make sure your skid steer or forktruck has the correct capacity to handle these when full.

Dimensions may vary slightly

| Yard Cap. | Width |

|---|---|

| 3 yard | 48" |

| 4 yard | 62" |

| 5 yard | 76" |

| 6 yard | 90" |

| 7 yard | 104" |

| 8 yard | 118" |

| 9 yard | 135" |

| 10 yard | 150" |

Heavy Duty Standard

2800 lb. capacity

12 ga hopper - 1/4" full length channel base

| WGT | Item # |

|---|---|

| 1200 lb | 300R28 |

| 1342 lb | 400R28 |

| 1430 lb | 500R28 |

| N/A | N/A |

| N/A | N/A |

| N/A | N/A |

| N/A | N/A |

| N/A | N/A |

Extra Heavy Duty

5000 lb. capacity

10 ga hopper - 1/4" full length channel base

| WGT | Item # |

|---|---|

| 1340 lb | 300R05 |

| 1482 lb | 400R05 |

| 1596 lb | 500R05 |

| 1720 lb | 600R05 |

| 2000 lb | 700R05 |

| 2200 lb | 800R05 |

| N/A | N/A |

| N/A | N/A |

Super Heavy Duty

7000 lb. capacity

7 ga hopper - 1/4" full length channel base

| WGT | Item # |

|---|---|

| 1515 lb | 300R07 |

| 1715 lb | 400R07 |

| 1859 lb | 500R07 |

| 2015 lb | 600R07 |

| 2400 lb | 700R07 |

| 2650 lb | 800R07 |

| 2888 lb | 900R07 |

| 3150 lb | 1000R07 |

Monster Bull Series

Our Largest Hoppers

Overall Length 102"

Overall Height 76"

Our largest-capacity hoppers - up to 12 yards. Make sure your skid steer or forklift has the correct capacity to handle these when full.

Dimensions may vary slightly

| Yard Cap. | Width |

|---|---|

| 8 yard | 82" |

| 10 yard | 102" |

| 12 yard | 122" |

Extra Heavy Duty

5000 lb. capacity

10 ga hopper - 3" High x 3/8" full length channel base

| WGT | Item # |

|---|---|

| 2375 lb | 800M05 |

| N/A | N/A |

| N/A | N/A |

Super Heavy Duty

7000 lb. capacity

7 ga hopper - 3" High x 3/8" full length channel base

| WGT | Item # |

|---|---|

| 2875 lb | 800M07 |

| 3175 lb | 10MB07 |

| 3450 lb | 12MB07 |

Popular Options

| Item # | Item Description |

|---|---|

| DFS | Dump-From-Seat™ Retractable Latch Rope |

| APD | Automatic Push-and-Dump from seat |

| BAPD | Automatic Push-and-Dump from seat (for Standard Models) |

| PC4S2R2 | 2" x 4" Phenolic Casters (2 swivel & 2 rigid). For Mini and Baby Bull Hopper Models. Adds 4-1/4" in height. |

| PC6S2R2 | 2" x 6" Phenolic Casters (2 swivel & 2 rigid). For Jr. Bull and Big Bull hoppers. |

| PC62R2 | 2-1/2" x 6" Phenolic Casters (2 swivel & 2 rigid. Standard on Brahma and Monster Bull Models. |

| PH | Push Handle (for use with casters) |

| HFL | Hopper Floor Lock |

Other Options

| Item # | Item Description |

|---|---|

| 3FP | 3” Fork Pocket instead of 2-1/2” |

| 3WE | 3 way fork entry |

| CPE2 | Set of 2 crane Pick Up Eyes |

| FRO | Fluid Reclaim Option |

| QAO | Skid Steer Quick Attach option |

| SF | Stack Feature on Hoppers up to 58” wide |

| DHP | 1” Drain Hole with Plug |

| LIDS | Optional Lid to keep contents contained |

More information on popular self-dumping forklift hopper options:

Automatic Dump-From-Seat™

A nylon leash extends or retracts as needed. The latch rope reel has a magnetic mounting clip, keeping the reel on the hopper when not in use. When in use, simply stick it to the forklift frame. To dump your trash hopper, just lock the thumb button and pull. After dumping, tilt the forklift mast back and the hopper will automatically roll back into its locked position again.

Automatic Push-and-Dump™ On Our Self Dumping Hoppers

The Automatic Push and Dump™ is designed for dumping into roll-offs or other large waste containers. By pushing the latch push tube gently against the edge of the large waste container, the hopper latch is released, dumping the scrap material quickly.

Capacity chart for our Self Dumping Hoppers

Note: each self dumping hopper within a particular series has the same height and length. Only the width varies to handle the different capacities. For instance, the Brahma Bull 4yd and the Brahma Bull 6yd are both 60”high and 90”long. Only the width is different. Use the following chart to help you choose the cubic size you need.

The Mini Bull series has an ultra low profile and is short. The overall height is 26”and the length is 38”. Designed for narrow or tight areas. Available in 1/8 yd. increments.

Capacity: 1/8 (17”W), 1/4 (30”W), 3/8 (42”W)

“Stretch”Series Capacity: 1/2 (57”W), 5/8 (70”W), 3/4, (84”W), 7/8 (98”W), 1yd. (111”W)

The Baby Bull Series is also a low profile hopper. The overall height is 30” and the length is

50”. This series is very popular in the wood working industry. It is ideal for placing beside

your table saw, or, with the Bat-Wing™ Base, underneath your chop saw bench.

Capacity: 1/3 (25”W), 1/2 (37”W), 3/4 (55”W)

“Stretch”Series Capacity: 1 (73”W), 1 1/4 (90”W), 1 1/2yd. (102”W)

The Junior Bull series is a medium height hopper. The overall height is 36”and the length is 66”.

Capacity: 3/4 (33”W), 1 (43”W), 1 1/4 (53”W), 1 1/2 (63”W)

“Stretch”Series Capacity: 1 3/4 (73”W), 2yd. (83”W)

The Big Bull series is our most popular. Overall height is 43”and the length is 72”. Be sure your

forklift has the correct capacity to handle these when full.

Capacity: 1 1/2 (46”W), 2 (58”W), 2 1/2 (72”W), 3 (86”W)

“Stretch”Series Capacity: 3 1/2 (100”W), 4 yd. (114”W)

The Brahma Bull series’ overall height is 60”and the length is 90”. These hoppers hold lots of

material! Be sure your forklift has the correct capacity to handle these when full.

Capacity: 4 (62”W), 5 (76”W), 6 (90”W), 7 (104”W), 8 yd. (118”W)

How tough do you need your hopper?

The Steps to Efficiency are:

Confirm: We confirm your hopper size and footprint before we ship your product.

Delivery: Our short lead times ensure that you receive your hopper quickly.

Enjoy: See increased efficiency, productivity, and regained space in your shop!

-

Confirm

We confirm your hopper size and footprint before we ship your product.

-

Delivery

Our short lead times ensure that you receive your hopper quickly.

-

Enjoy

Enjoy your increased efficiency, productivity, and regained space!

Specialty Self Dumping Hoppers

No matter what you need your hopper to do, we can make it!

Here are some of the specialty hoppers we have made…

Low-profile Stretch Hoppers

Perfect for small places like under work benches - especially when mounted with casters! Click here to see what's possible...

Hopper FAQ's & Warranty

Customer Support

Not sure which hopper would work best for your shop or your needs? Our team is here to help maximize your hopper's efficiency in your shop!

Warranty

All our hoppers come with a standard 90-day warranty that protects you from any mistake we make.

In-Stock Options

Our Quick Ship program offers a variety of size options that ship within 1-4 business days.

What if you had…

Our Scrap Hoppers help make this a reality for your company!

Self-dumping hoppers can be used in a variety of applications including...

-

- Woodworking

- Metal fabrication shops

- Pallet shops

- General manufacturing

Read more about applications in our self dumping blog article here.

Testimonials

Self-dumping forklift hoppers are designed to allow forklifts and other equipment with fork attachments to dump materials and scrap without any additional motors or pulleys being needed.

There is a release latch on self-dumping trash hoppers which allow the hopper to be easily dumped and emptied. When the load is dumped, the hopper closes on its own, and the release latch becomes locked.

Because they can be easily moved and dumped with a forklift, self-dumping hoppers are valuable in helping manufacturing plants catch, move, and discard scrap material.

This results in a safer workplace, cleaner shop floors, happier employees, and a more efficient manufacturing plant.

What Makes Iron Bull's Heavy Duty Trash Hoppers Unique?

Here at Iron Bull, we have done extensive research on many kinds of hoppers available in today's market.

We understand that there are many factors that go into making a safe, durable, and truly efficient self-dumping hopper. Some of these factors are the steel thickness, overall design, and the way the hopper is put together in the manufacturing process.

We have taken the strong points of other self-dumping dumpsters and put them into a single package in our deluxe heavy-duty hopper line:

- Wrap around lip on back corners

- Welded reinforcing angle around top edge

- Side of hopper extending down past the bottom and welded solid

- Welded gussets on inside front corners

These features, put together in one single hopper, add up to a well-built unit with great structural integrity.

Choosing the Hopper Steel Thickness

One of the most important factors in a hopper's structural integrity is the steel thickness.

The thicker or heavier the steel, the greater the hopper strength. Thicker steel also has greater resistance to “dings and dents” and punctures from heavy material or careless forktruck operation.

Each forklift dump hopper size has different steel thicknesses to choose from. The steel thickness of the hopper and the hopper base design determine the duty rating and rate capacity rating.

The duty ratings are an important selection factor. For instance, if the material being put into the hopper are heavy chunks of hardwood or metal that will fall with some force, then, even if the weight of a full hopper is less than the weight capacity, a heavier duty hopper will be a better choice.

The thicker steel in the heavier duty hopper will have greater “ding and dent” resistance which of course means fewer repairs and longer hopper life.