How we've helped other shops

0+

HoppersIn Use

A few of the companies that use our hoppers

Light-Weight Hoppers - 1000 lbs capacity

Ideal for….

- Wood scraps and light-weight scrap

- Woodshops, furniture stores, and other shops

- When casters are included, these are perfect for putting into hard-to-reach spaces to maximize your shop!

Get a quote today to see how you can revolutionize your wood or furniture shop!

Popular options for our bottom dump hoppers:

Casters

simple addition with a huge effect. Add ease of movement within your shop without using a forktruck, saving on propane and forklift wear and tear.

Automatic Dump-From-Seat™

A nylon leash extends or retracts as needed. The latch rope reel has a magnetic mounting clip, keeping the reel on the hopper when not in use. For in use, simply remove from hopper and magnetically stick it to the forktruck frame. To dump, just lock the thumb button and pull. After dumping, tilt the forktruck mast back and the hopper will automatically roll back into its locked position again.

Fork Extensions

Fork extensions allow bottom dump hoppers to be lifted over vehicles, furnaces, and other objects safely and easily without needing to worry about your forklift hitting the object.

Additional Options - please note that not all features are available for all models.

- Stacking feature

- 1" drainage hole

- Crane pick up eyes

- 3-way fork entry - (1/4 to 2 cubic yard only)

- Hopper floor lock - (for use with casters)

- 3" fork pocket - (our standard is 2 1/2")

- Push handle - (for use with casters)

- Bat-wing base

- Open-one-end with Back-stop

- Open on both ends

Iron Bull drop bottom hoppers come standard with a Gray oxide primer. The following colors are available as an option:

- Yellow

- White

- Green

- Red

- Black

- Blue

The Steps to Efficiency are:

Size: We discuss the hopper size and capacity that is right for your business.

Produce: We create your hopper to the exact specs and ship it.

Enjoy: See increased efficiency, productivity, and regained space in your shop!

-

Size

We discuss the hopper size and capacity that is right for your business.

-

Produce

We create your hopper to the exact specs and ship it.

-

Enjoy

Enjoy your increased efficiency, productivity, and regained space!

Standard Hoppers - 2000 lbs capacity

Single Door Drop Bottom

Double Door Drop Bottom

Ideal for….

- Larger wood scraps and medium metal scraps

- Woodshops, light-weight metal shops, and smaller manufacturing

- Available in single or double door options

Get a quote today to see how you can revolutionize your manufacturing shop!

Popular options for our bottom dump hoppers:

Casters

simple addition with a huge effect. Add ease of movement within your shop without using a forktruck, saving on propane and forklift wear and tear.

Automatic Dump-From-Seat™

A nylon leash extends or retracts as needed. The latch rope reel has a magnetic mounting clip, keeping the reel on the hopper when not in use. For in use, simply remove from hopper and magnetically stick it to the forktruck frame. To dump, just lock the thumb button and pull. After dumping, tilt the forktruck mast back and the hopper will automatically roll back into its locked position again.

Fork Extensions

Fork extensions allow bottom dump hoppers to be lifted over vehicles, furnaces, and other objects safely and easily without needing to worry about your forklift hitting the object.

Additional Options - please note that not all features are available for all models.

- Stacking feature

- 1" drainage hole

- Crane pick up eyes

- 3-way fork entry - (1/4 to 2 cubic yard only)

- Hopper floor lock - (for use with casters)

- 3" fork pocket - (our standard is 2 1/2")

- Push handle - (for use with casters)

- Bat-wing base

- Open-one-end with Back-stop

- Open on both ends

Iron Bull drop bottom hoppers come standard with a Gray oxide primer. The following colors are available as an option:

- Yellow

- White

- Green

- Red

- Black

- Blue

The Steps to Efficiency are:

Size: We discuss the hopper size and capacity that is right for your business.

Produce: We create your hopper to the exact specs and ship it.

Enjoy: See increased efficiency, productivity, and regained space in your shop!

-

Size

We discuss the hopper size and capacity that is right for your business.

-

Produce

We create your hopper to the exact specs and ship it.

-

Enjoy

Enjoy your increased efficiency, productivity, and regained space!

Heavy-Duty Models - 2000+ lbs capacity

Ideal for….

- Metal scraps

- Heavy-duty industries like metal fabricating shops, machining shops, etc.

- Hauling stone, gravel, and other aggregate materials

- True customization with hydraulic and controlled dumping options

Get a quote today to see how you can revolutionize your manufacturing and scrap disposal process!

Popular options for our bottom dump hoppers:

Casters

simple addition with a huge effect. Add ease of movement within your shop without using a forktruck, saving on propane and forklift wear and tear.

Automatic Dump-From-Seat™

A nylon leash extends or retracts as needed. The latch rope reel has a magnetic mounting clip, keeping the reel on the hopper when not in use. For in use, simply remove from hopper and magnetically stick it to the forktruck frame. To dump, just lock the thumb button and pull. After dumping, tilt the forktruck mast back and the hopper will automatically roll back into its locked position again.

Fork Extensions

Fork extensions allow bottom dump hoppers to be lifted over vehicles, furnaces, and other objects safely and easily without needing to worry about your forklift hitting the object.

Additional Options - please note that not all features are available for all models.

- Stacking feature

- 1" drainage hole

- Crane pick up eyes

- 3-way fork entry - (1/4 to 2 cubic yard only)

- Hopper floor lock - (for use with casters)

- 3" fork pocket - (our standard is 2 1/2")

- Push handle - (for use with casters)

- Bat-wing base

- Open-one-end with Back-stop

- Open on both ends

Iron Bull drop bottom hoppers come standard with a Gray oxide primer. The following colors are available as an option:

- Yellow

- White

- Green

- Red

- Black

- Blue

The Steps to Efficiency are:

Size: We discuss the hopper size and capacity that is right for your business.

Produce: We create your hopper to the exact specs and ship it.

Enjoy: See increased efficiency, productivity, and regained space in your shop!

-

Size

We discuss the hopper size and capacity that is right for your business.

-

Produce

We create your hopper to the exact specs and ship it.

-

Enjoy

Enjoy your increased efficiency, productivity, and regained space!

Watch how we solved this shop's scrap problem.

Wondering how a custom bottom-dump hopper could help your business be safer and more efficient? Get a quote today to get started!

Drop Bottom Hopper Specs, FAQ's, & Warranty

Customer Support

Not sure which hopper would work best for your shop or your needs? Our team is here to help maximize your hopper's efficiency in your shop!

Warranty

All our hoppers come with a standard 90-day warranty that protects you from any mistake we make.

In-Stock Options

Our Quick Ship program offers a variety of size options that ship within 1-4 business days.

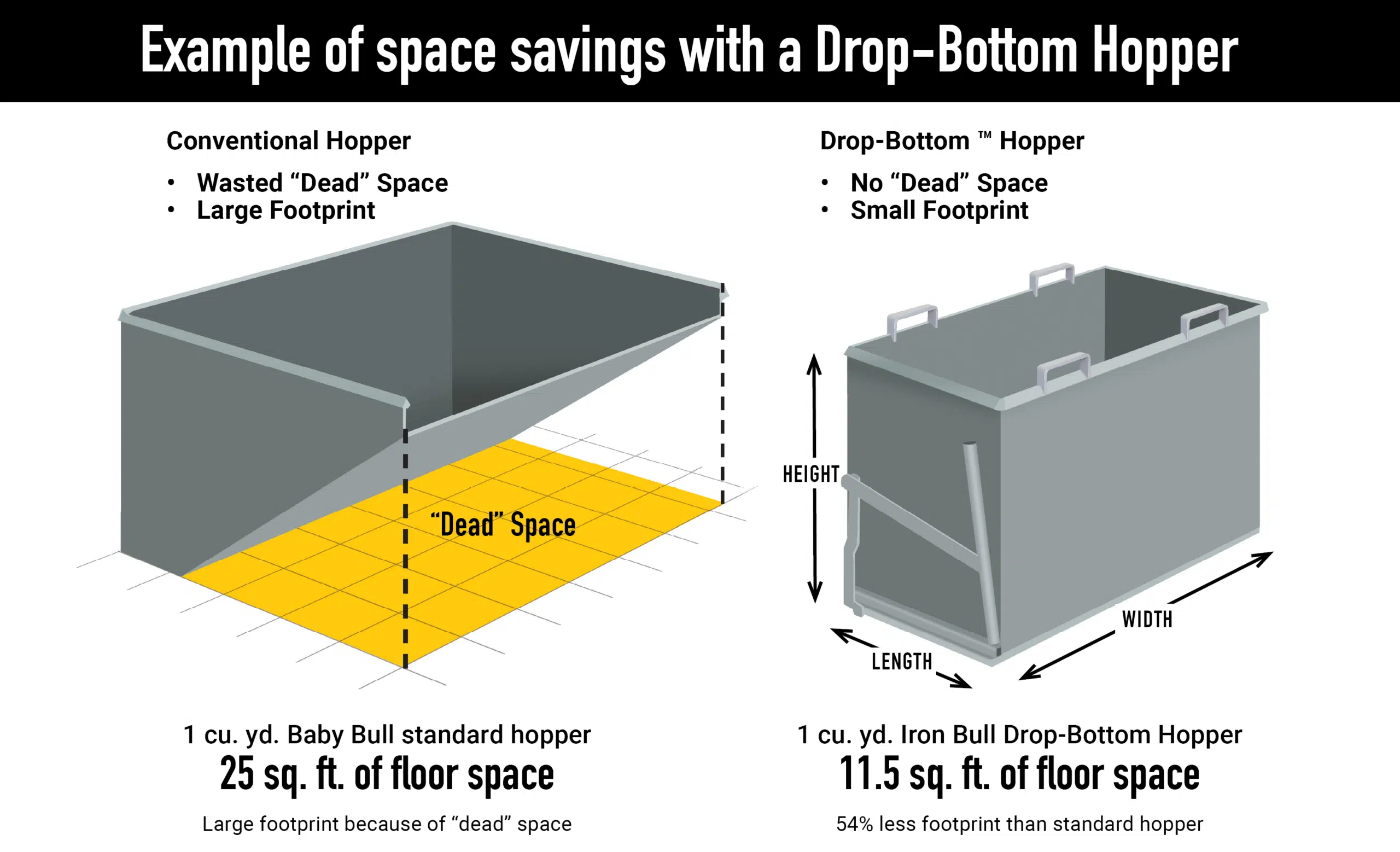

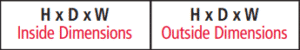

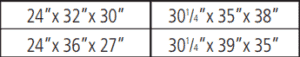

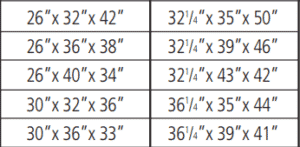

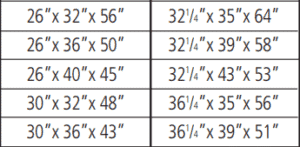

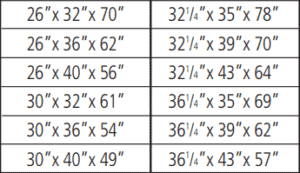

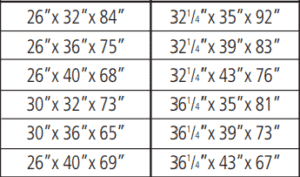

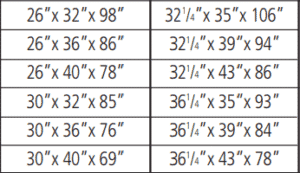

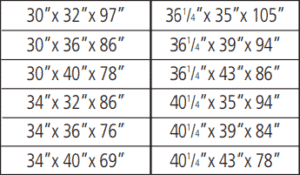

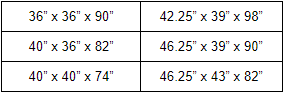

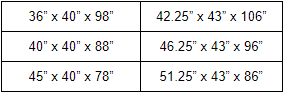

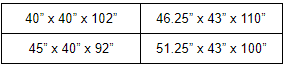

Sizing chart for our Drop Bottom Hoppers

All Drop Bottom Hoppers are made to our customer's specs. Order by giving the inside dimensions. Keep in mind that the overall dimensions are larger.

To get overall dimensions, add the following:

- 8 1/2" to the WIDTH

- 3" to the DEPTH

- 2" to the HEIGHT

- 4" to the overall height if ordering casters

Drop Bottom Hopper steel is 12 gauge. Heavier gauges are available.

To calculate capacity: Find the inside box height by multiplying the HEIGHT x WIDTH x DEPTH in inches. Divide this number by 46,656 to find cubic yards.

Example: You want the inside of the hopper to be 30" high, 36" deep, and 65" wide. Multiplying these three numbers gives 70,200 inches. Divide by 46,656, and you will need a Drop Bottom Hopper of 1.5 yards.

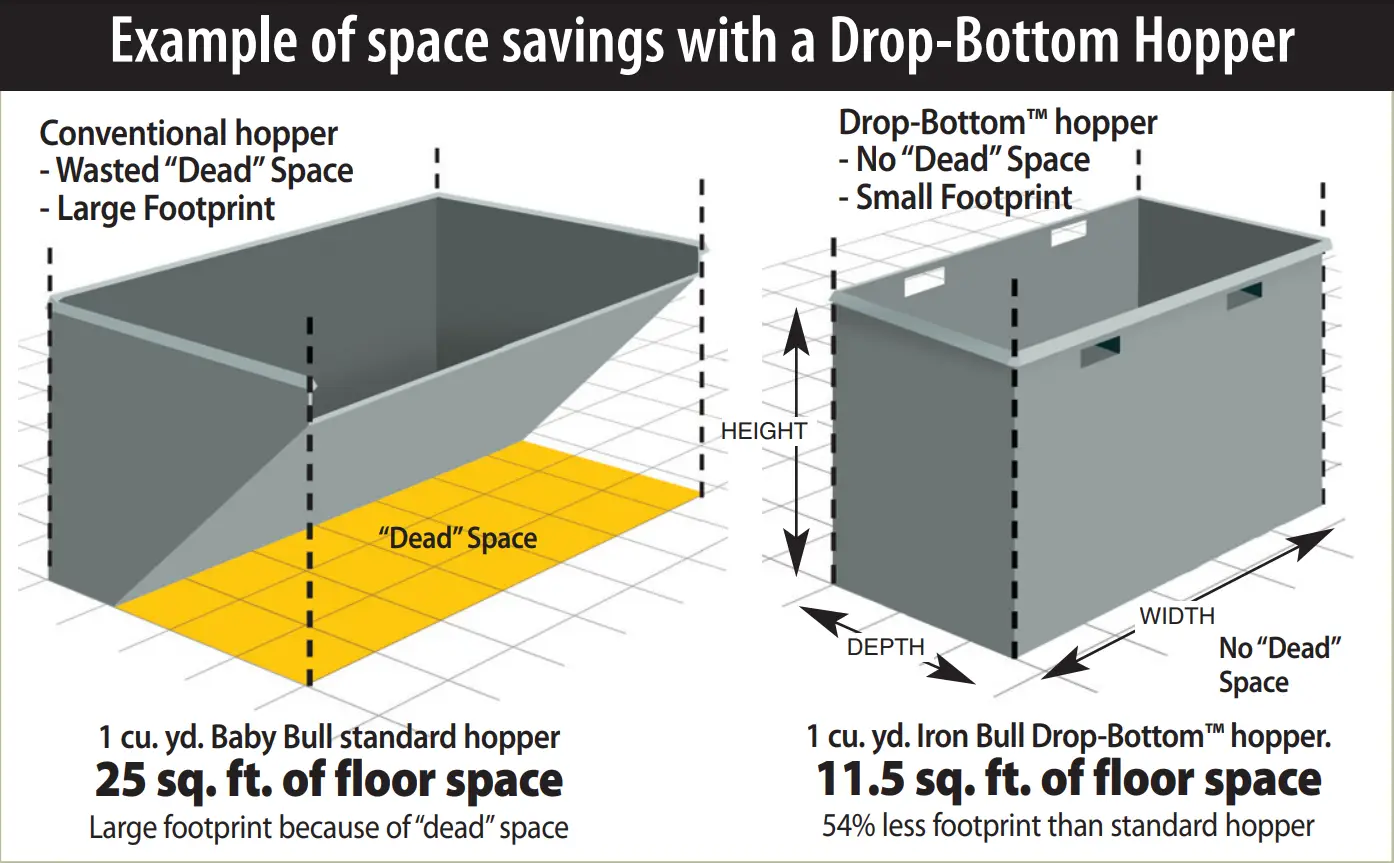

Iron Bull drop bottom hoppers, also known as bottom dump hoppers, make use of every square inch of floor space. You can now put a trash or scrap hopper in the tightest of areas wherever you need them to maximize production. Iron Bull bottom dump hoppers come as narrow as 20.” You can’t find that anywhere else!

We started manufacturing drop bottom hoppers when managers at a large aluminum process plant asked for a hopper to fit into tight spaces for collecting scrap aluminum.

To meet this need, we designed a forklift dump hopper where the bottom opens up to discharge the scrap. When the company managers saw the efficiency of the bottom dump hopper and how little space it took, they immediately ordered more!

Many woodworking and furniture shops have tight spaces and need something small for collecting wood scraps. Drop bottom hoppers fit this need well.

With a wide range of bottom dump hoppers, Iron Bull works with many wood shops and manufacturing plants to provide small hoppers that fit into tight spaces.

Our bottom dump hoppers come with two dumping options: A single drop door and a double bottom dump. The double bottom dump hopper allows for precise controlled dumping of aggregrate material such as sand, dirt, stone, and more.

Self-dumping hoppers can be used in a variety of applications including...

-

- Woodworking

- Metal fabrication shops

- Pallet shops

- General manufacturing

Read more about applications in our self dumping blog article here.