5 Lean Manufacturing Principles & 10 Tools You Need For Your Manufacturing Plant

As a business owner, you are continually trying to make your business more profitable, and you probably have a list of ideal processes to increase your profits.

These ideals look great on paper, but we all know putting them into practice is much harder than writing them down.

Life constantly throws wrenches into our systems and causes delays, problems, and even quality issues.

But what if your business could achieve the following results:

- 80% or more waste reduction

- 50% lower production cost

- 50% higher labor productivity

- Less inventory

How are these results possible in today’s manufacturing world?

With the Lean Manufacturing system.

Lean Manufacturing is a business model that strives to minimize waste in manufacturing while increasing efficiency and productivity. The Japanese are credited for its beginnings, specifically the Toyota Motor Corporation.

In this article, Iron Bull Manufacturing is going to look at the five main principles of Lean Manufacturing. We will also look at ten of its practices that you can apply to your manufacturing plant.

Are you ready to increase your productivity while reducing waste?

Keep reading to learn the Lean Manufacturing principles to take your production and profits to the next level!

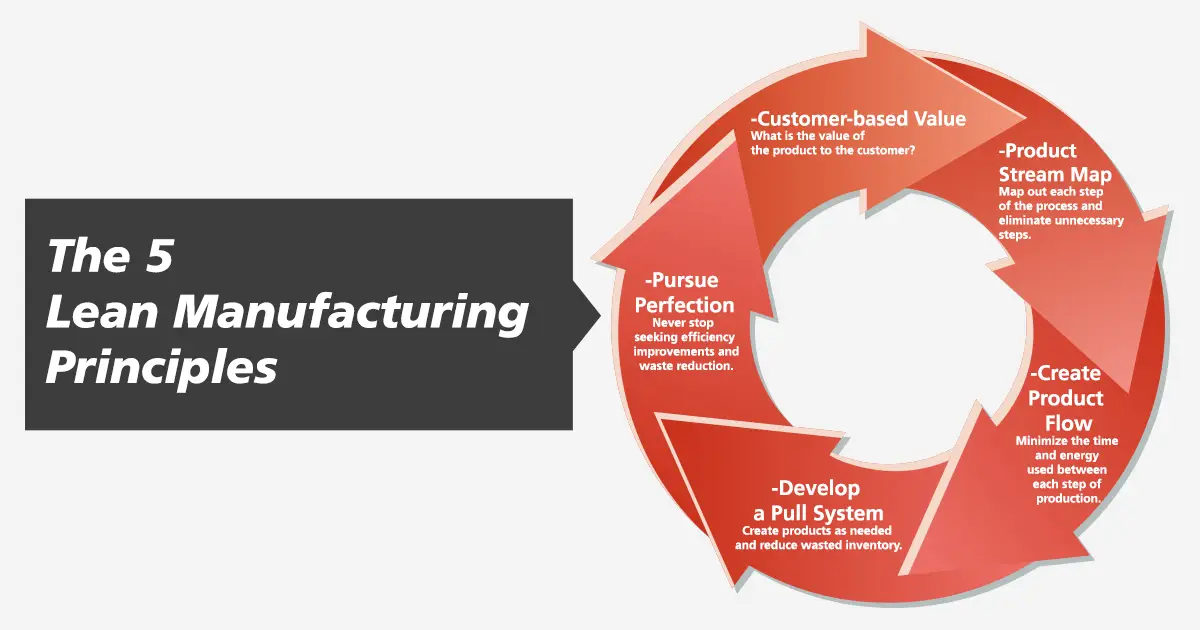

5 Lean Manufacturing Principles

There are many specific tips, tricks, and applications of Lean Manufacturing, but they all fall under the five main principles of Lean Manufacturing.

These principles are also sometimes referred to as The Cycle of Lean Manufacturing because they continue building on each other to make a more efficient business.

What is the goal when applying these Lean Manufacturing principles?

It’s simple - a production system that produces better products faster and with less waste. Sounds ideal, right!

Customer-based Value

When businesses price a product, they typically look at their cost of materials, development and manufacturing costs, and overhead. Using these factors, they give their product a selling price.

Customer-based value flips this model.

Instead of the business setting the selling price, the customer sets the price. The business views its product from the customer’s perspective by asking these questions:

- How does the product benefit the customer?

- What value would a customer place on the product?

- What would a customer be willing to pay for the product?

- The answers to these questions provide the selling price.

If this selling price is lower than the business wants, then it needs to explore how to cut waste and cost while increasing productivity. in order to produce the product at the price the consumer wants.

Thankfully the other four Lean Manufacturing principles and tools help reach this goal!

If the customer-based selling price is higher than the current selling price; however, the business should be able to raise the price and increase its product margin.

Product Stream Map

Have you ever looked at an insect or flower petal under a microscope? The amount of detail you can see on the specimen is mind-boggling, but when you focus so closely on one thing you lose sight of the big picture.

Creating a product stream map helps you keep the big picture in mind and allows you to identify problem spots in your manufacturing business.

The first step in reducing waste is by looking at each step of the manufacturing process. This is called “mapping the value stream” or “product steam map.”

The business begins by taking one of its products and maps out each step of the manufacturing process. This map begins at the very beginning with the raw materials entering the facility, and it ends with the final product being shipped out the door.

Creating the product stream map is a lot of work, but it reveals several things:

- The steps that can be reduced, combined, or even eliminated

- Where waste is present. This waste could be wasted material, unnecessary storage space, excessive manpower, inefficient processes, etc.

To protect from burnout, it is best to apply the product stream map and Lean Manufacturing principles to one product at a time. After all, trying to change everything at once simply overwhelms the people making the changes.

That's why we recommend starting with your best-selling product or lowest-margin product.

Create Product Flow

Imagine this:

You clean out your basement and have to move a bunch of boxes to the garage to get the job done. However, in a couple of months, you need that space in the garage and realize you need to move the boxes back to the basement.

You've just wasted a lot of time and energy (and probably got a backache too!)

One of the biggest wastes in many manufacturing plants occurs when products are being transported between stations or require storage between stations. Every time you move a product it takes up time and energy.

Using an assembly-line production helps reduce this issue but doesn’t completely eliminate it.

Creating a product flow is the natural next step after completing your product stream map.

The goal is to minimize the time, energy, and storage required to move your product and raw materials from the beginning to the shipping stage.

Each step of the product flow needs to be in order, streamlined, and efficient to reduce waste and increase productivity.

Achieving this may require moving workstations, automating parts of the process, or adjusting the manufacturing process to reduce storage space, manpower, or downtime.

Curious about how you can create great product, and flow models? Read our blog 7 Types of Waste in Lean Manufacturing and How to Reduce Them.

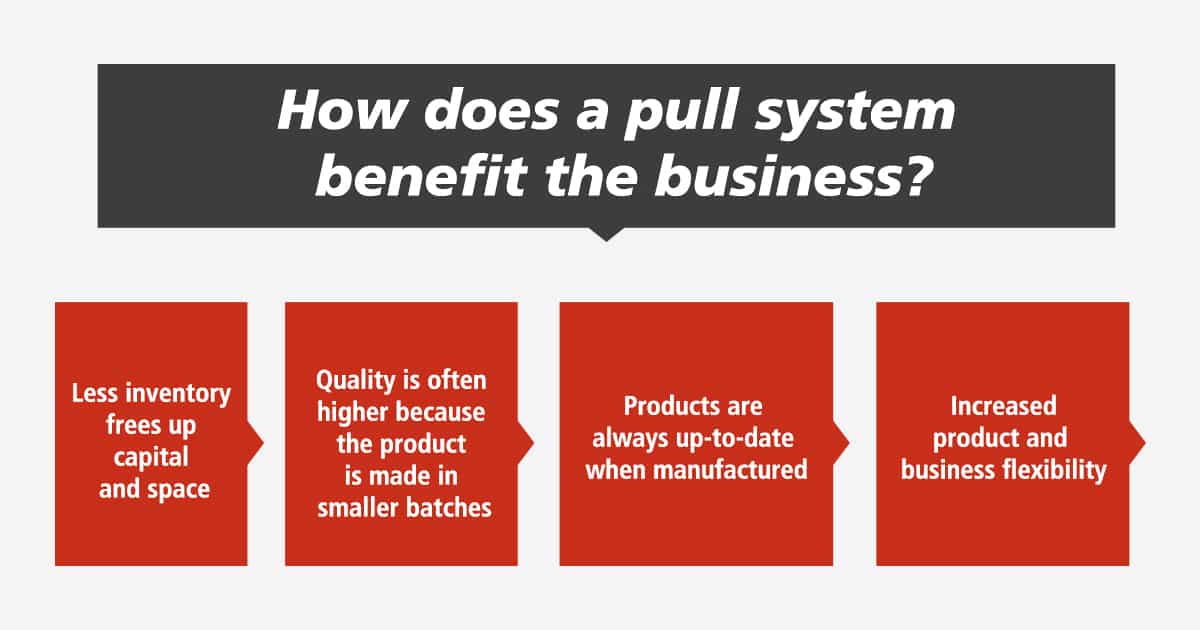

Develop a Pull System

To make stock and space more efficient, Lean Manufacturing relies on a pull system instead of a push system.

A push system, which is used by most manufacturing companies, relies on forecasts, having plenty of raw material on hand, and having a stockpile of inventory ready to ship.

This system gets its name by always trying “to push” its products into the market.

While this push system may seem ideal for maximum sales, it has several negatives:

- Market forecasts are rarely accurate

- Stockpiles of raw materials or inventory tie up space and capital

- The company can get stuck with too much product

The alternative is developing a pull system.

When a business has made its assembly line truly efficient and streamlined, it can manufacture products much more quickly.

Therefore, a business practicing Lean Manufacturing does not need as much inventory. Instead, when orders come in, they quickly manufacture parts to meet the order and keep a minimum inventory ready to ship.

How does a pull system benefit the business?

- Less inventory frees up capital and space

- Quality is often higher because the product is made in smaller batches

- Products are always up-to-date when manufactured

- Increased product and business flexibility

Pursue Perfection

Once you have gone through the Lean Manufacturing process for a product, continue using the cycle for other parts of your business!

Like anything else in business, pursuing perfection means you are continually trying to make your processes more efficient and better quality.

In pursuing perfection, it is crucial to involve your whole staff and employees, down to the last one.

The input of plant managers, or the employees who work with the equipment every day, provides incredible feedback on what is wasting time, resources, or space.

If you apply these Lean Manufacturing principles to your product lines and manufacturing processes, you are sure to see improvements in efficiency and a reduction in waste!

And remember: stay persistent. Often it seems like a process is as efficient as possible, but by applying the methods described above you can continue to cut out unwasted time and motion.

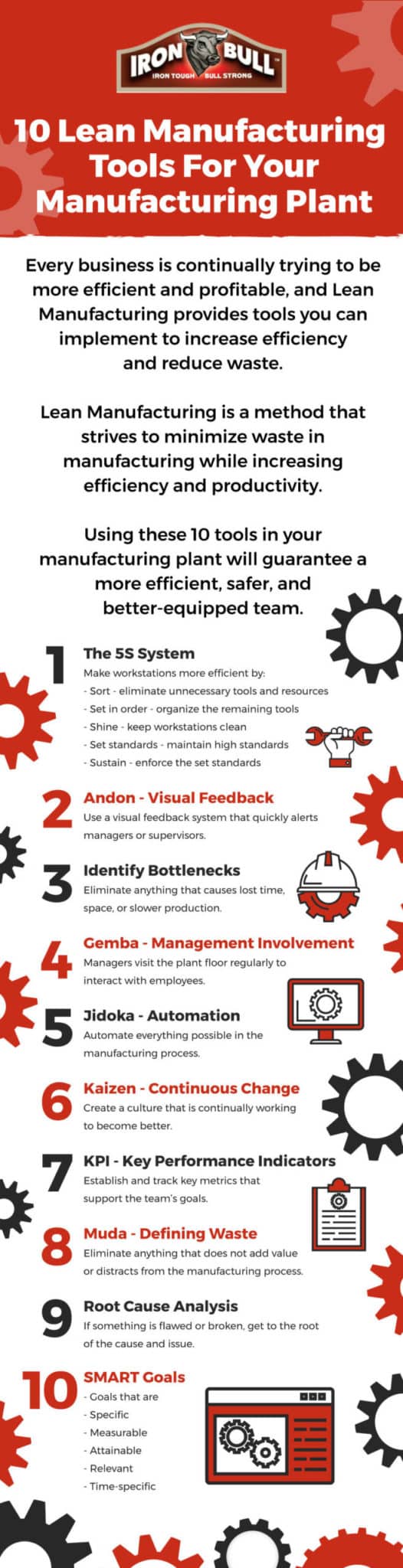

10 Lean Manufacturing Tools For Your Manufacturing Plant

There are many ways, tools, and methods to apply the Lean Manufacturing principles in any business, but not all the tools apply to every business.

In this section, we look at ten Lean Manufacturing tools that work well in manufacturing facilities.

We include these 10 tools in an infographic at the end of the article. If you would like to jump directly to the infographic, click here.

The 5S System

The 5S System works best when applied to each manufacturing station or workplace on the manufacturing floor, and it includes the following:

- Sort - eliminate the tools or resources not needed at the station

- Set in order - organize the remaining necessary tools

- Shine - keep the workstation clean and inspected regularly

- Set standards - set and maintain high standards for the above steps

- Sustain - make sure the set standards are followed and enforced

Andon - Visual Feedback

Andon is a Japanese term referring to a system where employees can quickly notify management, supervisors, or other employees of a production or quality issue.

The feedback system can consist of basic alerts using lights, switchboards, colors, flags, etc. It can also be more advanced and consist of electronic signals.

No matter what system you use, the goal is to address issues in the manufacturing process quickly so manufacturing does not become bottlenecked.

Identify Bottlenecks

Bottlenecks are any part of the manufacturing process that limits or impedes the overall manufacturing cycle.

Bottlenecks cause multiple forms of waste, including lost time, space, and slower production.

Identify the bottlenecks on your plant floor and work to eliminate them.

Gemba - Management Involvement

Meaning “the real place” in Japanese, Gemba refers to the place where the actual work gets done in a plant - the manufacturing floor.

Because the plant floor is the heartbeat of the company, managers need to visit the floor regularly, and be engaged with what goes on there.

Not only does this help improve employee interaction and morale, but it also allows upper-level management to see what is hurting the manufacturing process.

By interacting with the employees who run the machinery and assembly line, management obtains a better understanding of what is working and what needs improvement.

Jidoka - Automation

Jidoka simply refers to using automation when applicable to help in the manufacturing process.

Automated systems help improve efficiency, reduce downtime, and usually are programmed to shut down immediately if something breaks. It's a great way to increase your efficiency.

While automation usually has a significant upfront cost, it is essential to compare this with labor savings and plant efficiency. Many times automation pays for itself quickly, but careful analysis needs to be made before making significant changes.

Kaizen - Continuous Change

Kaizen is the Japanese term for “change for better,” and it refers to a business culture that is continually striving to become better. It's the constant search for perfection.

Kaizen does not only refer to upper-level management or supervisors. Instead, true Kaizen requires every employee to be involved in the process.

Why is 100% employment participation so important?

When employees know they are valued and heard in making change, several things happen:

- Faster buy-in to the changes

- More suggestions on ways to change

- Better focus on making the changes work

KPI - Key Performance Indicators

A business’s KPIs are the metrics used to track progress toward established goals.

For example, if a company wants to increase its production of a product by 50% in one year, they need to make a list of KPIs for this to happen.

To achieve this goal, the company could have these example KPIs:

- Train five additional employees how to run the machinery

- Reduce scrap material by 10%

- Have the equipment and manufacturing line running 1 hour longer each day

- Spend 30 minutes at the end of each day cleaning and organizing the machinery and workspace to increase efficiency

The KPIs need to be clear, measurable and known to all employees.

As the year progresses, the company’s KPIs show how they are doing in reaching their goals and what adjustments need to be made to achieve success.

Muda - Defining Waste

Defined as “futility, uselessness, or wastefulness,” Muda defines waste as anything not adding value or distracting from the overall process.

Throughout the manufacturing process, it is critical to identify any material, steps, or process that is not helping the overall efficiency of the plant. Once identified, these need to be eliminated.

These trouble spots then need to be analyzed and corrected to reduce Muda and wasted resources.

Root Cause Analysis

When an essential piece of equipment has a breakdown, how does your company address the repairs?

Do you apply a quick fix so the machinery is running quickly, even though you know it could break down again soon?

Or do you take some extra time to analyze the issue thoroughly and make necessary repairs and adjustments?

Root cause analysis is looking closely at anything broken, and it doesn’t just apply to machinery.

When something breaks down or is flawed, it is essential to get to the root of the problem instead of applying a quick bandaid.

One way to analyze the issue is to ask the question “Why” at least five times. This process helps discover what the actual problem is at the root and how to fix it properly.

SMART Goals

Similar to KPIs, SMART Goals focus on having practical and achievable goals.

The SMART acronym stands for goals that are:

- Specific

- Measurable

- Attainable

- Relevant

- Time-specific

For example, a company could have the following generic goal:

“We strive for a clean manufacturing floor.”

While this goal expresses an ideal, no one knows what it means, and the floor probably remains only semi-clean. The company could replace this generic goal with a SMART goal:

“Every Friday from 4:00 to 5:00, each employee will clean the floor and machinery of their workstation.”

This goal spells out exactly what needs to happen and when, and will result in a safer and cleaner shop floor.

Trash Hoppers in Lean Manufacturing

When manufacturing plants go through the Lean Manufacturing process and begin applying the Lean Manufacturing tools, many realize they lack easy and efficient scrap removal.

Hoppers, also referred to as trash or scrap hoppers, provide an efficient and safe way to store, move, and dispose of scraps.

Because they vary in size and fit into almost any space, trash hoppers keep manufacturing plants cleaner, safer, and more organized.

Hoppers are not only used for scrap, however. They are also ideal tools for moving raw materials or finished products around, especially in woodworking or metal fabricating shops. There are even special hoppers designed for getting sawdust out of the air.

At Iron Bull Manufacturing, we manufacture high-quality trash hoppers. Every hopper comes with a 90-day warranty and Satisfaction Guarantee.

How do different hoppers help achieve Lean Manufacturing?

Self-dumping hoppers - Easily transfer and dumping of either scrap or raw materials. They can be designed to be dumped directly from a forklift!

Stretch hoppers - Similar to self-dumping hoppers in their design, stretch hoppers allow for the storage and transport of longer pieces of material, product, or scrap.

Bottom-dump hoppers - These hoppers maximize the footprint and available space of the hopper. They are designed to fit into tight spaces to make good use of every inch of the plant floor.

Sawdust hoppers - They allow clean and safe storage and disposal of sawdust in woodworking plants.

If you are interested in learning more about hoppers, get a hopper quote from Iron Bull Manufacturing today or read our blog post on the main types of hoppers.

Conclusion

No matter the stage, age, or size of your business, we always want to have better efficiency, increased productivity, and less waste. Continually improving these things helps your business grow.

The tools and principles of Lean Manufacturing are some of the best ways to begin moving toward these goals.

If you apply these Lean Manufacturing principles to your business, you will see the benefits and enjoy a more streamlined operation!

At Iron Bull Manufacturing, we are always working to help our clients be more efficient in their processes and systems.

To help efficiently manage, store, and move materials, products, and scrap; we offer a variety of hoppers that work with a forklift or pallet jack.

Whether it is our self-dumping hoppers, bottom dump hoppers, or specialty hoppers that we make specifically for your shop, we continue to help our clients win with excellent processes, products, and customer service!

We also provide a variety of tractor shade canopies, including:

- John Deere ROPS and tractor canopies

- International ROPS and tractor canopies

- Oliver tractor canopies and support frames

- Massey-Ferguson tractor canopies and support frames

- Ford tractor canopies and support frames

Knowing and addressing the Lean Manufacturing wastes in this article, or implementing the main principles and tools of Lean Manufacturing discussed in our previous post, helps make any company and industry more efficient, safer, and more profitable.