Bottom Dump Trash Hoppers: Styles, Uses And Benefits (plus real-life examples of using them)

For many people, getting rid of their trash is easy - toss it in the recyclable or disposable bin and let a truck haul it away each week.

But how about a manufacturing plant that creates enormous volumes of trash or a township whose waste contains oil?

Now just throwing the trash into a dumpster has serious problems.

For one, traditional dumpsters are huge containers that waste a lot of space and have no easy way to be moved or emptied. On top of that, many items have to be separated out of dumpsters.

And unfortunately, the consequences of improper waste management are numerous:

- Decreased workplace efficiency

- Dirty and dangerous workspaces

- Unsatisfied workforce

At Iron Bull Manufacturing, we know how managing your physical workspace can be a complete game-changer. We want to help you reduce waste so you can focus on the things that are crucial to your business.

Through our years of experience, we’ve come to passionately believe that bottom dump hoppers can revolutionize every business that has to deal with waste.

Ready to find out how you can save tons of time and boost profit? Let’s get to it!

What Is A Bottom Dump Hopper?

Trash hoppers are a variation of dumpsters, and their primary purpose is to collect trash and scrap.

However, trash hoppers are designed to allow forklifts and other equipment with fork attachments to move and dump the hoppers so you can manage waste more easily and efficiently.

Within the category of trash hoppers, you can find various styles of hoppers uniquely designed to offer a solution for every trash problem you face.

For example:

Self-dumping hoppers are versatile containers used in many industries like woodworking, manufacturing plants, construction sites, lumberyards, and CNC machining.

Self-dumping hoppers come in a variety of styles and are very easy to use. You can get a low-profile hopper to slip under a workbench or a stretch hopper for extra-long scrap. You can even design a completely custom hopper to fit your unique needs!

No matter what style of self-dumping hopper you choose, you can easily dump it using a forklift. The container dumps in a swivel motion like a tractor bucket - and hence its name: “self-dumping hopper.”

And if you don't have a forklift, or have terrain that a forklift can't traverse? No worries! Trash hoppers can also be moved using a skid steer or anything else with forks which is why they are sometimes called forklift dumpsters. Small ones can even be dumped with a pallet jack!

In our opinion, the crown jewel of the trash hopper industry is the bottom dump hopper.

These amazing trash hoppers can be used in nearly every imaginable scenario (more on that later) and can handle astounding amounts of weight.

They are appropriately named since the waste drops directly out the bottom of the hopper (rather than the hopper tipping like most self-dumping ones do).

Now, let’s dive into the details of bottom dump hoppers and see why they are the best trash hopper in the industry!

Bottom Dump Hopper Styles

There are a variety of styles when it comes to bottom dump hoppers. You can differentiate between the styles according to this criteria:

- How does the scrap exit the hopper?

- Is the hopper enclosed or open?

- Where are the fork pockets located?

We’ll look at each of these questions and discover the options you have when it comes to bottom dump hopper styles.

How Does Scrap Exit The Hopper?

There are two primary ways to dump the trash from a bottom dump hopper.

1 - Single-door configuration

Very simply, a single-door design has one door on the bottom of the hopper that hinges open to allow scrap to exit the hopper.

The single-door, bottom dump hoppers can handle around 6,000 pounds of waste before they have to be emptied. Of course, if the hopper can be placed on a flat surface before pulling the dumping lever, you can add more weight.

2 - Double-door configuration

As you might expect, a double-door configuration is a bottom dump hopper with two doors on the bottom. The doors split in the middle and swing outward when the operator empties the load, and the scrap falls out the bottom.

This unique design allows a double-door, drop-bottom hopper to do some pretty cool stuff!

- The double-door configuration can handle even more weight than the single door design since the load is distributed on two doors instead of one.

- Waste material is guaranteed to drop directly out the bottom of the hopper, which means you can easily control where it goes.

- The hoppers can be lifted into higher containers since the doors don’t take up as much space when they swing open as a single door.

Once you’ve decided how many doors you want on a bottom dump hopper, you can determine what system you want to use to open the doors.

Again, there are two options.

1 - Lever operated

Lever-operated dumping mechanisms are the most common when it comes to bottom dump hoppers. Operating them is extremely simple - you don’t even have to leave your seat! All you have to do is pull a strap or cable attached to a lever on the hopper that controls the doors.

Pull the lever, and the doors open, emptying your load in a matter of seconds. We’re not kidding - it’s that easy. You can be back to work in a matter of minutes.

2 - Hydraulic operated

Some bottom dump hoppers utilize hydraulics to open and close the doors.

This is particularly helpful for granular products like sawdust, gravel, or powder since hydraulic hoppers can dump their load slowly. This controlled flow creates less dust when you dump the material.

The hydraulic operated doors are also easy to operate. Simply pull the cord and watch the hydraulics do the work for you.

Is The Hopper Enclosed Or Open?

The second significant distinction in drop-bottom styles is the difference between enclosed and open hoppers.

Enclosed hoppers are often referred to as sawdust hoppers, but in reality, they are useful for capturing and storing any kind of granular material. You could use them for sawdust, sand, gravel, stone, or any other loose material.

These hoppers often come with an inlet port that can be securely connected to a dust collector or fan.

That means the waste from your shop goes directly into the enclosed hopper without you ever even touching it. Less dust and less work is always a good thing. Just think about having less sawdust on all the surfaces in your shop, less sawdust in your nose, lungs, and hair, and less to clean up!

Some businesses even use enclosed hoppers in their cyclone systems.

Open hoppers have an open top and are used for collecting larger trash items.

When it comes to what kind of trash can be stored in open hoppers, feel free to let your creativity run wild!

For example, at Iron Bull Manufacturing, we can build specialty hoppers that allow you to separate liquid materials like water and oil from the rest of the scrap.

Here’s a real-life example of what we’re talking about:

Several months ago, a Caterpillar dealership contacted us with a special request.

They were dealing with waste that included water - but they wanted to reuse the water that got discarded with their trash.

We built them a dewatering hopper that separated the water from the waste after it was dumped in a bottom dump hopper.

The result?

Hundreds of saved man-hours since they didn’t have to separate the water and waste manually!

(To learn more about hopper styles, read our blog: 4 Main Types of Hoppers And Their Uses.)

Where Are The Fork Pockets Located?

The third and final distinction in bottom dump hopper styles is the location of the fork pockets.

Most bottom dump hoppers have fork pockets at the top of the hopper. This is different from the standard self-dumping hopper design, which has fork pockets on the bottom of the hopper.

Some drop bottom hoppers have fork pockets in the middle of the hopper. This means the hopper doesn’t have to be lifted as high to empty into other containers.

However, bottom dump hoppers with fork pockets in the middle can only be used with granular products.

Benefits Of A Bottom Dump Hopper

Now you know about bottom dump hoppers - perhaps you have a few ideas of how you creatively incorporate a drop-bottom hopper into your business.

If so, drop a comment at the end of this article. We love getting new ideas from industry experts!

But we still haven’t hit the bottom line:

How can a bottom dump hopper benefit your business?

Let’s find out!

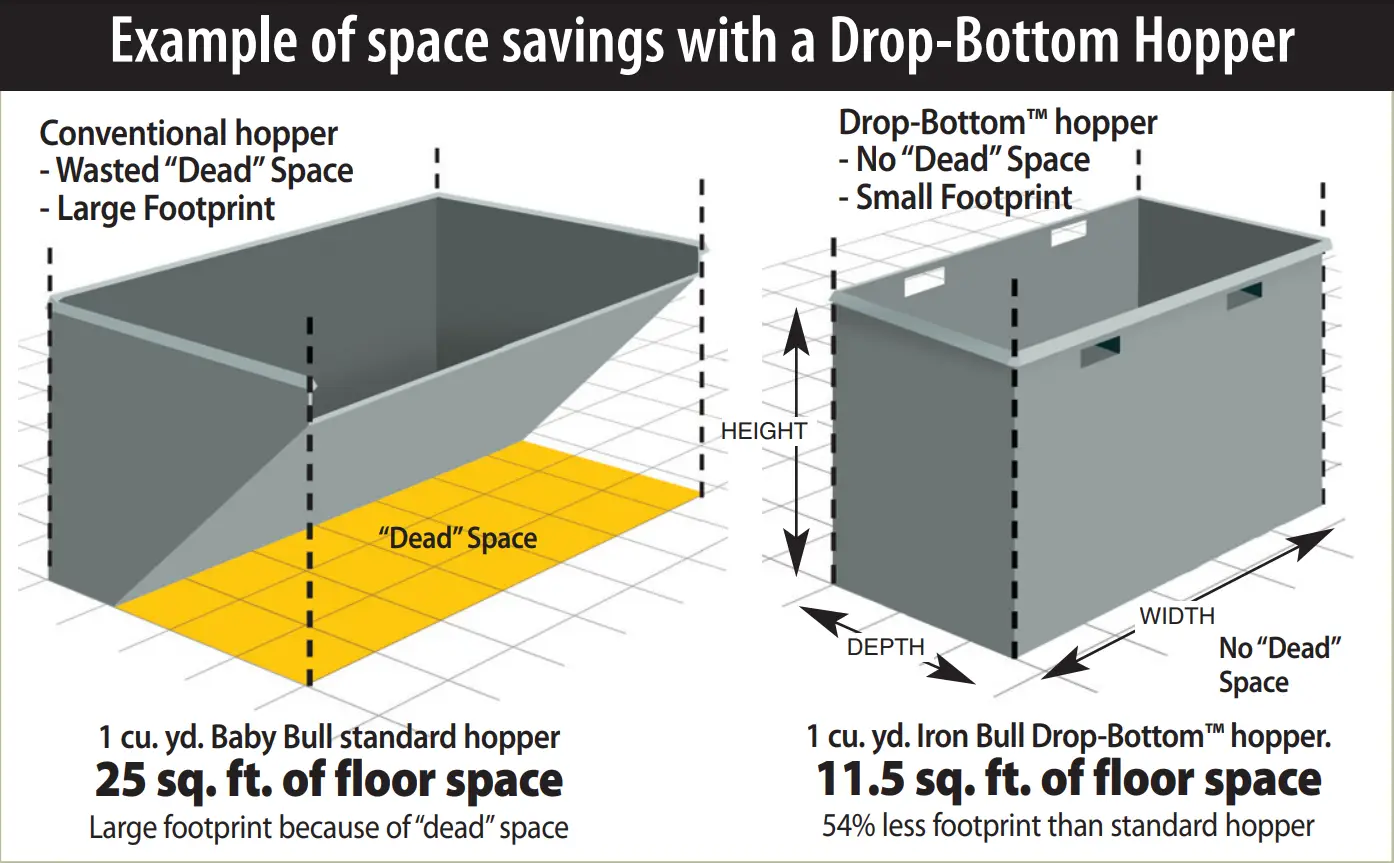

Maximize Every Inch Of Work Space

What if you had more space because everything fit in your shop perfectly, like the pieces of a puzzle?

You’d be guaranteed greater safety and efficiency.

And while any trash hopper helps make your worksite more efficient, bottom dump hoppers stand head and shoulders above the competition in this area.

Why?

Drop bottom hoppers don’t have a dumping mechanism like other self-dumping hoppers. That means they can be designed with a rectangular shape and utilize every ounce of the hopper’s footprint.

Precise And Consistent Material Control

Trash hoppers are incredibly useful because they allow for efficient waste storage and disposal.

However, when the hoppers malfunction and don't operate correctly, you lose the advantage you gained in purchasing a trash hopper. But unfortunately self-dumping hoppers malfunction sometimes.

Self-dumping hoppers rely on proper weight distribution to tip forward and pour waste out the front of the hopper. That means that if the products in the hopper are too light, or if heavy products are in the back, it might not dump.

On top of that, the swinging forward motion of self-dumping hoppers is not very precise when it comes to where the waste will land. And the out of control motion can be somewhat dangerous to employees who are in the wrong spot at the wrong time.

Watch this video to see how some delf dumping hoppers have an uncontrolled dumping action.

Drop bottom hoppers solve both of these problems.

Since the bottom simply “drops away” in drop bottom hoppers, the waste is guaranteed to come out. It’s merely gravity at work!

And you can also rest assured that the waste material will go precisely where you want it - directly underneath the bottom dump hopper!

Endless Design And Customization Options

Because bottom dump hoppers have such a unique design, the customization options are almost endless.

Do you need a higher or wider hopper? Perhaps you want a hopper with sloped sides or a hopper with crane hooks.

No worries - a bottom dump hopper can easily be built to fit your exact needs.

In fact, a drop bottom hopper can be modified to work in ANY situation 90% of the time.

We’ll even help you brainstorm to find creative solutions to your waste management problems. Send us a picture or contact us, and we can help you find a design that works.

Versatility Among Industries

Because you can modify bottom dump hoppers to fit your exact needs, you can use them in a vast array of industries.

In other words:

If your business creates scrap, a bottom dump hopper can help you.

While standard self-dumping hoppers are almost exclusively used in the woodworking and steel industries, bottom dump hoppers can be used for anything from concrete projects to municipalities.

In fact, we’ve been conducting a study here at Iron Bull.

We’ve been coding all our customers - marking those that aren’t in the woodworking or steel industries with an “x.”

Over the past several months, more drop-bottom hoppers were sold to specialty industries marked with an “x” than to steel or woodworking companies.

Hopefully, you understand how valuable this flexibility is!

If you’ve been wringing your hands in the past because there is no waste management solution for you, you can stop now.

But here’s the thing:

Of course, it’s easy for us to speak highly of a product that we sell. We understand if that smells fishy.

That’s why we want to give several real-life examples of ways bottom dump hoppers were used to make unique industries more efficient.

Three Examples Of Bottom Dump Hoppers In Action

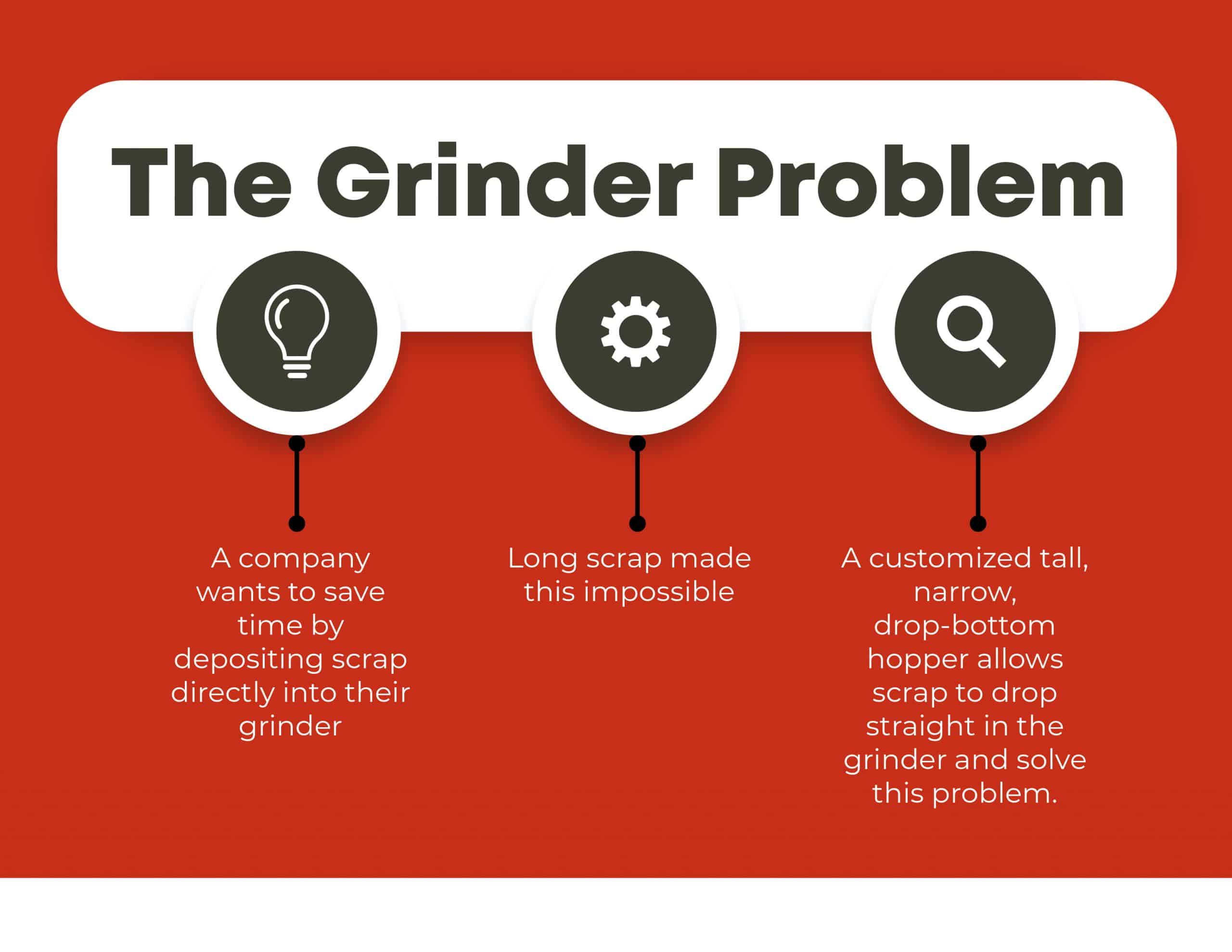

Example #1

A company wanted to reduce wasted motion and save time and energy by having their scrap deposit directly into a grinder.

However, the majority of their scrap was lengthy - and the top opening to the grinder was relatively small.

With a regular self-dumping hopper, there would be no way around this conundrum. You can’t possibly dump long scraps sideways into a small opening.

However, we were able to design a tall narrow bottom dump hopper that fit on top of the grinder. The scrap was placed vertically in the hopper at the workstation, then the hopper was placed on top of the grinder. When the doors opened, the scrap fell straight down into the grinder, no mess, no fuss.

Mission accomplished!

Example #2

One company wanted a self-dumping hopper that could fit into a pit. Their idea was to then remove this hopper and empty it into a larger hopper that would eventually be emptied into a dumpster.

Using a bottom-drop hopper design, we were able to design a hopper the pit could accommodate.

On top of that, we outfitted the hopper with crane hooks so the hopper could be pulled out and emptied directly into the large dumpster.

For this company, using a customized bottom dump hopper saved them one whole step in waste management, resulting in saved time, space, and money!

Example #3

Another company wanted a hopper that could handle pressure.

That’s because they wanted to use a vacuum-style design to suck granular material into the hopper for storage.

No problem!

We made a special port for this installation and adjusted our enclosed design to make sure it could handle the pressure - literally!

No Extra Cost For Size Customization

Most customization costs money.

For example:

If you want to engrave your name on a leather mousepad or get a special mug for your significant other, you are bound to pay a few extra dollars.

Most of the time larger customized items are the same way--you have to pay extra for the customization.

But Iron Bull does things differently: we offer size customization at no extra cost.

We’re not kidding. You don’t pay an extra cent to adjust the size of a drop bottom hopper from Iron Bull.

Instead, we base our pricing on the capacity of the hopper you are ordering, not the level of customization.

In other words:

A larger hopper does cost more than a small hopper because of its increased size capacity. And as a result, if you add 2 feet in width to a standard hopper size, you will pay more than usual.

However, this extra cost comes only from the increased capacity of the hopper - NOT the size customization. As a result, the increased price is quite minimal.

To be clear, special features that do not relate to size like crane hooks, or slatted side walls do come at a minimal extra cost.

We do our best to bring this straightforward approach to all the business we do - and that’s why working with us is so incredibly easy.

- Get a quote or give us a call. You can be sure that we’ll only give our honest advice and you’ll receive no pressure to buy.

- Let us build the perfect drop bottom hopper for you.

- Enjoy the benefits of a safe, clean, and efficient workspace!

It’s seriously that easy!

Conclusion

Imagine reducing waste, lowering production costs, and increasing productivity.

You can do all three by utilizing a bottom dump hopper in your place of business.

If you aren’t sure what kind of work best in your situation, that’s completely fine. That’s why Iron Bull is here. We’d love to apply our knowledge to your unique situation and help you find the best fix.

And we offer much more than just trash hoppers.

We also provide a variety of tractor shade canopies, including:

- John Deere ROPS and tractor canopies

- International ROPS and tractor canopies

- Oliver tractor canopies and support frames

- Massey-Ferguson tractor canopies and support frames

- Ford tractor canopies and support frames

Contact us or get a quote today. We look forward to hearing from you!