An Introduction to Custom Hoppers

There’s nothing more frustrating as a business owner than needing a piece of equipment that doesn’t exist on the market.

Sometimes, when doing complex tasks, you can envision the type of equipment that could make the job much safer and more efficient. But what if the piece of equipment you can so clearly see in your head doesn't exist in real life?

Here at Iron Bull, we understand that your business has unique needs that aren’t always solved by standardized machinery. That’s why we create custom trash hoppers to solve your specific problems, saving you time and money in the long run.

But is a custom hopper right for you?

Keep reading to learn more about what hoppers are used for and how a custom hopper may be what your business needs!

What Are Hoppers Used For?

A hopper is a large tapered container with a dispenser at the bottom, used for many industrial purposes. For instance, a hopper could hold dust, gravel, coffee beans, firewood, steel shavings, or any other material you wish to collect and then dispense out the bottom at some point.

As you can imagine, the type of hopper you need depends on what you’re using the hopper for. For instance, hoppers used for dust collection are different from hoppers used for construction cleanup.

At Iron Bull, we make various types of trash and scrap hoppers. If you’re interested in knowing more about the different types of hoppers out there, feel free to read our blog posts about bottom-dump hoppers, self-dumping hoppers, and forklift dumpsters!

Hoppers vary in size, shape, dumping mechanism, and what type of equipment they can be moved with. Typically, hopper companies will have standard hopper types and sizes, and customers can pick the hopper that best suits their needs. Some companies, such as Iron Bull, go a step further and offer custom sizing for those who need it.

But that’s just the start of the customization Iron Bull can offer you! Our specialty custom hoppers offer more than just size modifications—they are fully customized to your specifications. For instance, if the standard hoppers don’t fit your space correctly, we can modify the shape of the walls for you. That way you are sure to get the exact hopper you need for your space and task.

Let’s look at some reasons you may need a fully customized hopper for your business.

Four Reasons You May Need a Custom Hopper

Businesses purchase custom hoppers for all sorts of reasons, but four reasons come up repeatedly as we talk to people about their custom hopper needs.

Reason 1: Safety

Safety should always be a top concern to you. Depending on your situation, you may wish to customize your hopper to make it safer.

For example, one thing we’ve done several times recently is installing a remote-controlled hydraulic dumping mechanism, allowing you to stand clear of the trash hopper while the contents are being dumped. If you’re working with stuff like scrap iron that could injure you if you tripped or in places where you could fall, dumping your hopper via remote control eliminates stumbling hazards.

Reason 2: Convenience

Sometimes you could easily perform currently inconvenient tasks with the right hopper. You may want a hopper that is modified to increase speed and efficiency, saving the company time and money overall. Of course, what those modifications are will depend on what the task is!

Reason 3: Fitting your equipment

You may want a specialty hopper designed to fit a specific type of equipment that’s not standard. For example, we’ve been approached by customers who use Quick Attach skid steer attachments and want their hopper to attach quickly to the skid steer in the same way.

Reason 4: Solving your problems

In general, people look to custom hoppers when they have a unique problem to solve that can’t be fixed by anything ready-made and already on the market! In that case, your only option is a customized solution.

Examples of Custom Hoppers

As you’ve probably realized by now, hoppers have almost infinite customization options! That means you are sure to be able to get a hopper that fits your needs.

Let’s look at a few examples of custom hoppers we’ve made here at Iron Bull so that you can get a better idea for all the possibilities.

Crane-operated hopper with remote release

We were approached by a company doing landscaping on an upper story of a multi-story building. Of course, this meant they needed to haul many materials such as mulch and dirt up to the site with a crane.

We developed a remote-controlled hydraulic dumping system for them. This allowed the crane operator to haul up the materials, position the hopper in the correct area, and then release the materials using the remote control. Then the materials could be easily distributed.

Since that whole process could now be done by one person, it saved the company a lot of time and effort.

In-floor hopper for scrap metal

A steel mill approached us, wanting a hopper that fitted into the floor so that employees could easily sweep small scraps of metal directly into the hopper. Then, the hopper could be picked up with a crane, taken out, and dumped.

Here’s the problem: on our regular drop-bottom hoppers, the latch mechanism that holds the gate open and closed is located on the outside of the hopper and adds an extra five or six inches to the hopper circumference. So if you set the hopper down into a hole, it leaves space on the side for scraps to fall alongside the hopper instead of into it.

To solve this problem, we created a custom hopper with tapered sides. The lip of the hopper now came to the edge of the hole in the floor on all sides. Problem solved!

Hopper with side chute

Hoppers, by definition, are filled at the top and dumped out the bottom. However, a customer approached us with a unique idea: could we make them a hopper that dumped out the side instead of the bottom?

We worked with them to create a unique hopper that fit the vision they had in their heads. Instead of a normal drop-bottom, we made a chute with a slide gate on the side. The unit sat on little legs, and the material now came from the side instead of the bottom, making it easy to, for instance, park a wheelbarrow next to it and fill it up from the hopper.

As you can see, the types of modifications customers ask for vary widely depending on what kind of work they do! But overall, these custom hoppers happen the same way:

- A customer has a unique situation in which a standard hopper doesn’t quite do the job

- They come to us with their idea

- We work with them to create a hopper that works for their situation and fulfills their needs

You can see more examples of our custom hoppers by viewing our custom hopper gallery!

How to Work With Us to Create Your Custom Hopper

Do you have a problem at your business that a standard hopper doesn’t quite solve?

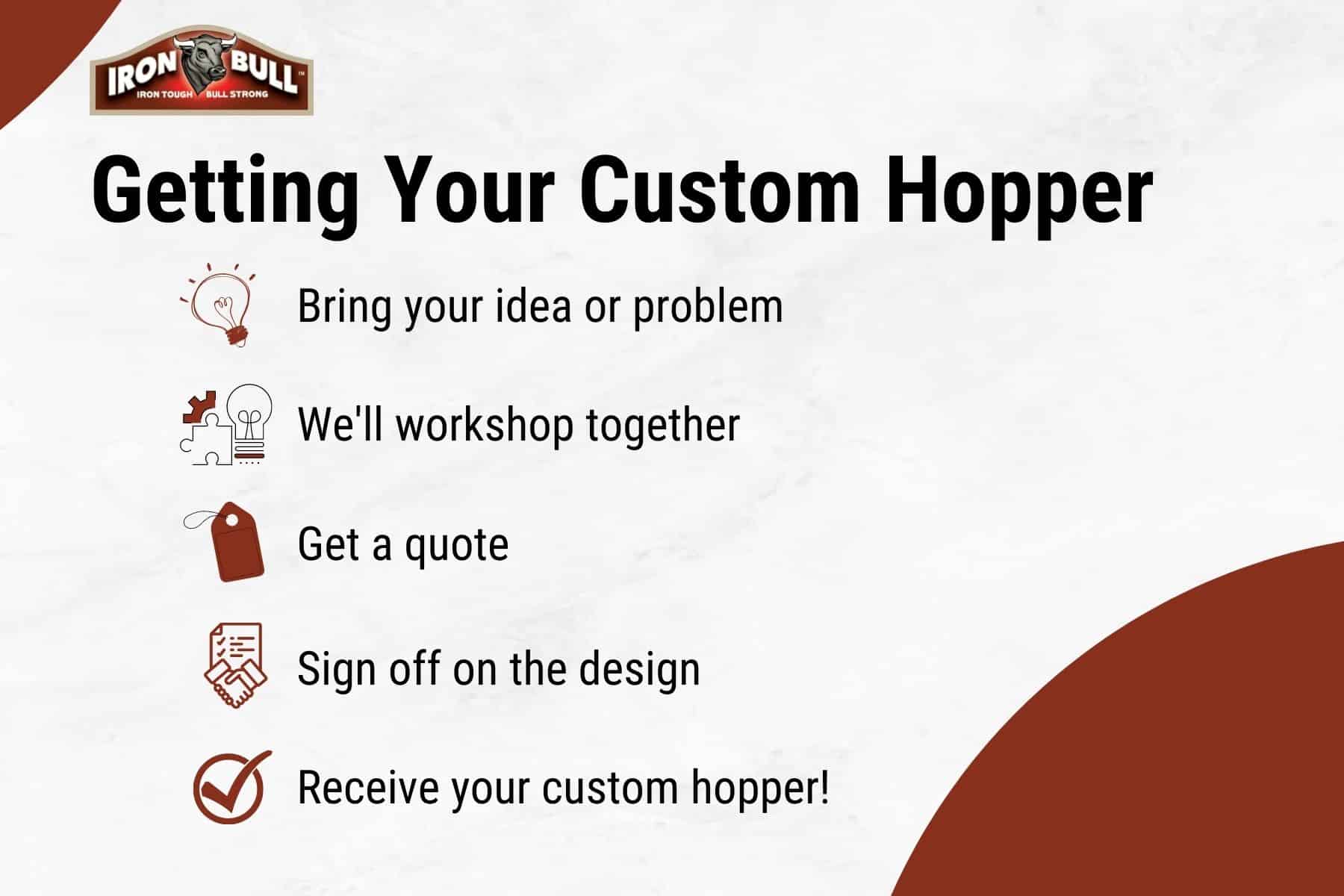

At Iron Bull Manufacturing, it’s easy to work with us to create a custom hopper that fits the bill. Just follow these five simple steps:

- Bring us your idea or problem. What type of hopper are you envisioning? What problem are you trying to solve?

- We will workshop your idea together. This is a collaborative process. You tell us what you need, and we’ll try to figure out how to make it happen.

- Get a quote. The cost of your hopper will depend on its size and complexity, but we’ll give you an estimate range early on. Once we’ve finalized the design, we can give you a more specific estimate.

- Sign off on the design. We’ll create a detailed drawing, and once you sign off on it, we can start making your custom hopper! Or, if the design doesn’t quite look like what you want, we’ll go back to the drawing board.

Receive your new custom hopper! After we’ve created your hopper according to your specifications, you can look forward to giving your employees a smoother, time-saving experience with your new custom hopper!

If, for any reason, your hopper does not live up to your expectations, give us a call. We’ll go back to the drawing board to ensure you get what you need. If we’ve made a mistake, don’t worry, we’ll fix for free! Otherwise, we’ll work with you to see how we can change the design to make it work as you envisioned.

Are you interested in a custom hopper?

Contact us today for more information or to tell us about your idea!

Besides custom hoppers, we also sell several other hoppers, such as

- Quick-ship hoppers

- Self-dumping hoppers

- Bottom-dump hoppers

- Sawdust and dust hoppers

- Forklift dumpsters

- Construction hoppers

- Low-profile hoppers

We’re committed to creating safe, strong, and efficient equipment that follows all state regulations and guidelines and does the job well.

You can read our reviews or view our hopper gallery if you want to know more.

Then, be sure to contact us because we’d love to hear from you!