How to Choose the Right Self-Dumping Forklift Hopper for Your Business

Do you have a workshop where you wish you had more space so that everything would fit exactly like it should? Have you considered streamlining your scrap removal process for better output in your manufacturing?

Having a self-dumping forklift hopper makes for a more efficient and organized workplace.

Your shop will be clean and clutter-free, and your scrap will be continuously collected and easily disposed of.

At Iron Bull Manufacturing, we get it. We understand that a clean and organized workplace is efficient, and we have made over 5000 hoppers for our clients, saving them over 375,000 hours and $9 million in labor each year. This blog will use our experience and expertise to help you choose the right self-dumping hopper for the job.

Ready? Let’s hop to it!

Table of Contents

What Does a Self-Dumping Hopper Do?

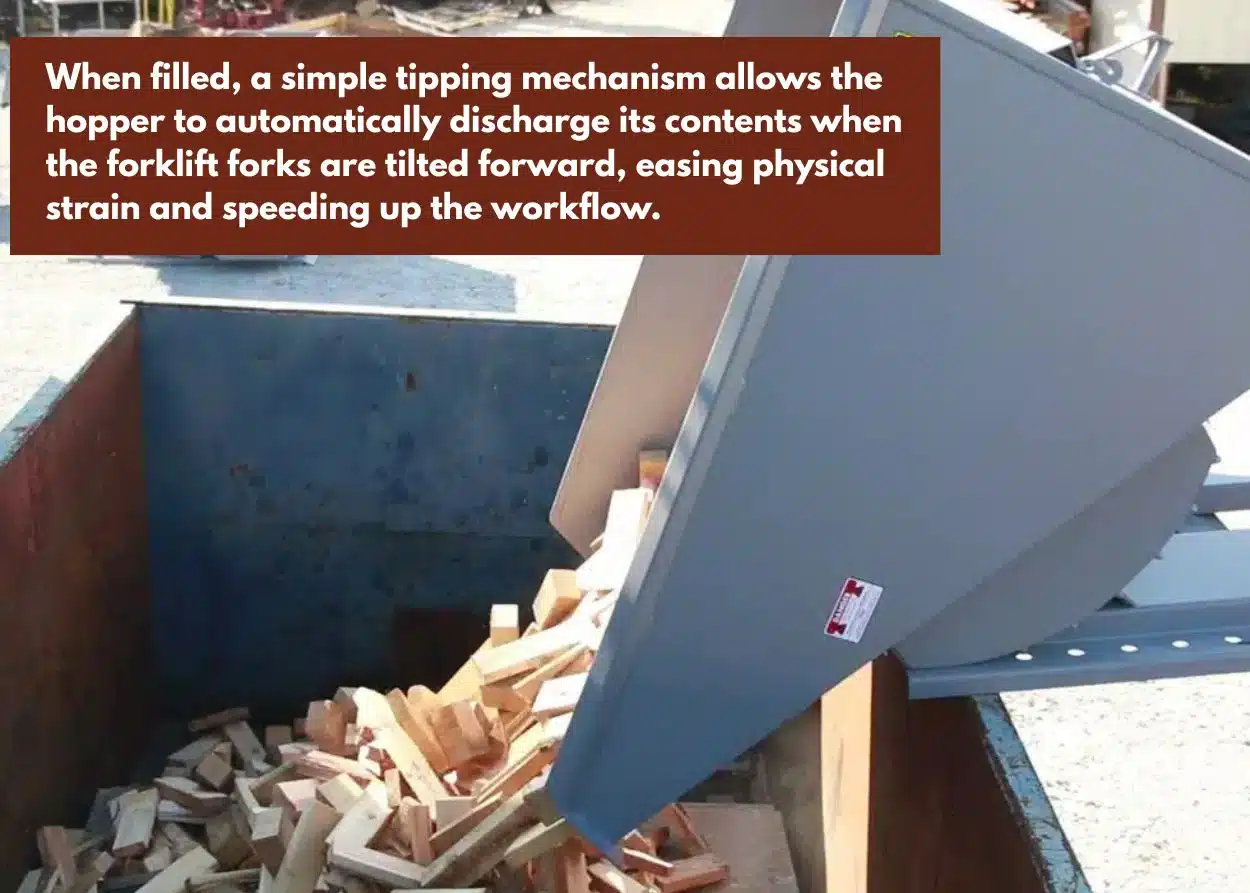

A self-dumping hopper is a disposal hopper designed to streamline the collection, movement, and disposal of materials. It’s engineered for efficiency and safety, reducing manual labor and minimizing risks in industrial settings. A forklift picks up the hopper to transport and dump waste or recyclable materials with minimal manual intervention. When filled, a simple tipping mechanism allows the hopper to automatically discharge its contents when the forklift forks are tilted forward, easing physical strain and speeding up the workflow.

The way it works is a thing of beauty: The self-dumping mechanism typically consists of a latch or trigger system that releases when the forklift's forks reach a certain angle. This action causes the hopper to pivot, allowing gravity to empty the contents. Once emptied, the hopper returns to its upright and locked position, ready for the next load.

This mechanism saves time and enhances safety by minimizing worker interaction with potentially hazardous materials. By investing in a self-dumping forklift hopper, businesses can achieve a clean workspace through streamlined waste management processes.

Benefits of Self-Dumping Hoppers

You’ve already got some trash cans around the workshop, so what’s the big deal? Just toss the trash into the cans and wheel them to the dumpster, right?

That’s easier said than done. When disposing of waste in containers they’re not designed for, the risk of accidents and injury increases. Cuts, scrapes, and bruises are likely, but so are deep lacerations, impalement, and even death.

Workers must know that their employer places their safety at a premium. Not only do self-dumping hoppers let your employees dump debris safely, but they also increase productivity. Here are some benefits to using a self-dumping hopper in the workplace:

- Increased Efficiency: Material handling and disposal processes are streamlined, reducing downtime and improving productivity.

- Enhanced Safety: Minimizes worker interaction with potentially hazardous materials and heavy loads. Just move the hopper to the dump, release the contents, and leave.

- Versatility: Adaptive designs mean the hopper can be used for various materials, including waste, recyclables, construction debris, and agricultural products.

- Reduced Labor Costs: Decreases the need for manual labor, saving on staffing and associated expenses.

- Improved Workplace Cleanliness: Promotes a cleaner and more organized work environment by efficiently managing waste and debris.

Some other benefits can be gained from using such equipment to keep your workers and workplace safe. As part of a safety management system, it can help reduce your insurance costs, so think of a self-dumping hopper as an investment towards a safer, more efficient workplace.

Key Factors to Consider

When choosing a self-dumping forklift hopper, the weight capacity must be considered. The best hopper for your business should adequately handle the volume of materials you typically process without compromising safety or exceeding the recommended load limit. Exceeding the hopper’s weight capacity could lead to equipment failure, workplace hazards, and unnecessary downtime.

The material type and size of the hopper are other critical considerations:

- Steel is commonly used for its durability, although specific applications might require other materials to reduce costs or move corrosive substances. Different materials like plastic or aluminum may be suitable for particular applications where weight reduction or corrosion resistance is a priority.

- Size and capacity should align with your operational scale—select a compact hopper for smaller volume needs and larger units for high-capacity loads. Standard self-dumping hoppers come in sizes from ¼ to 5 cubic yards and various capacities:

- 2000lb capacity: ideal for general paint maintenance, lightweight recycling, cardboard, light wood, and metal scraps.

- 4000lb & 6000lb capacities: These handle bulkier and heavier wood and metal scraps.

For heavy-duty work, we also offer a range of deluxe heavy-duty self-dumping hoppers that are regarded as some of the strongest on the market.

Note that hoppers may have the same height and length but not the same width. The width varies to handle the different capacities needed. For example, our Brahma Bull series hoppers are 60 inches high and 90 inches long, but have widths ranging from 48 inches to 76 inches to accommodate different volumes.

Consider these dimensions to ensure you get the most efficient product adapted to your specific operations.

Safety Features to Look for in a High-Quality Forklift Hopper

Safety is a top priority when handling materials with heavy equipment. A high-quality self-dumping forklift hopper should have features that bolster safety beyond mere durability. Quality hoppers have automatic latching systems, allowing secure transportation without the risk of accidental dumping. A well-built hopper will also include a bumper or other mechanisms to prevent wear and tear on forklifts during dumping.

Some other features to look for are:

- Automatic Latching System: A secure latching system is essential to prevent accidental dumping during transport. Look for a hopper with an automatic latch that engages when the forklift is upright and releases only when the forklift's forks are tilted forward for dumping.

- Forklift Wear Protection: Dumping can stress the forklift's forks and carriage. A well-designed hopper will include features to minimize wear and tear, such as bumpers, wear plates, or reinforced contact points.

- Visibility Enhancements: High visibility is crucial for safety in busy work environments. Choose a hopper with bright colors or reflective strips to make it easily visible to forklift operators and other workers.

- Load Containment: Features such as sidewalls, baffles, or enclosed designs can help prevent materials from spilling or shifting during transport, reducing the risk of accidents and material loss.

- Stability and Balance: The hopper should be designed to maintain stability and balance during lifting, transport, and dumping, even when loaded with uneven or bulky materials.

At Iron Bull, we take quality and efficiency very seriously. A durable, well-made product means a better return on your investment and an assurance that you’re less likely to have downtime because of equipment failure. Also, getting things done right the first time means better productivity.

Best Practices for Maintaining and Using Your Self-Dumping Hopper Efficiently

Even the best self-dumping forklift hopper requires proper maintenance to keep it functioning optimally, so here are some recommendations to keep your hopper in tip-top condition:

- Regular Inspections: Inspect the hopper regularly for signs of wear and tear, damage, or malfunction. Pay close attention to the latching mechanism, hinges, wheels, and fork pockets. Address any issues promptly to prevent further damage and ensure safe operation.

- Cleaning: Keep the hopper clean and free of debris to prevent material buildup, corrosion, and operational issues. Regularly remove any accumulated material and wash the hopper with water and mild detergent as needed.

- Lubrication: Lubricate moving parts such as hinges, pivots, and wheels according to the manufacturer's recommendations. Proper lubrication reduces friction, wear, and the risk of component failure.

- Operator Training: Ensure all forklift operators using the hopper are appropriately trained on its safe operation, including attachment and detachment procedures, dumping techniques, and load-handling best practices.

- Maintenance Schedule: Establish a routine maintenance schedule for the hopper and adhere to it diligently. Regular maintenance can prevent minor issues from escalating into significant problems and extend the hopper's lifespan.

- Load Management: Avoid overloading the hopper beyond its weight capacity. Distribute loads evenly to maintain balance and stability during lifting and transport.

- Safe Handling: Operate the forklift and hopper safely and responsibly. Follow all safety guidelines and procedures, and always be aware of your surroundings. Operators should wear some PPE, such as eye and breathing protection, in case the dumping process kicks up debris dust.

- Storage: When not in use, store the hopper in a clean, dry, and secure location to protect it from the elements and unauthorized use.

Is There a Self-Dumping Hopper For My Business?

Not all self-dumping hoppers are the same. Iron Bull makes specialty hoppers to address specific needs, such as:

- Low-profile stretch hoppers: Place these under or beside workbenches so you can slide your waste straight into the hopper instead of gathering it and transporting it to a trash can!

- Slab wood hoppers: Easily store, carry, and dump large lumber and scrap wood pieces.

- Scoop & dump hoppers: Scoop and dump granular products with your forklift using this hopper!

- Laser skeleton hoppers: Dumping those bulky skeletons from your laser cutting machines can be hazardous due to their sharp edges. Keep your people safe by using the hopper to dump the waste without contacting the contents.

These are just some hoppers that can help you optimize your workflow. We understand that each workplace is unique, so we can work with you to design the style, size, and durability you need for your hopper to fit your business's unique requirements.

Conclusion

Choosing the right self-dumping forklift hopper ensures your workflow remains smooth, efficient, and safe. At Iron Bull Manufacturing, we are committed to helping businesses find the right solutions for their machine attachment needs. By utilizing our expertly crafted products, which are equipped with the highest safety standards and modern efficiencies, you are better equipped to enhance your workspace and operational processes.

Ready to ramp up efficiency and safety at your workplace? Contact us today to explore premium quality equipment that helps you work smarter!