Low-Profile Hopper FAQs: Everything You Need to Know

Summary:

Low-profile hoppers are ideal for efficient material handling in tight spaces due to their shorter height and wider base, making them suitable for industries like manufacturing, warehousing, construction, and agriculture. To choose a low-profile hopper, consider its footprint, mounting, and how it integrates with your workflow, as well as the right material and capacity for your specific needs. Performing regular maintenance such as hinge and weld inspections, greasing moving parts, and balanced loading can help ensure the hopper’s longevity.

If you're tight on space but still need to move bulk materials efficiently, you've probably heard about low-profile hoppers. Maybe you’ve seen them in a catalog or at a trade show. Or maybe your crew mentioned them during a forklift run.

If so, you probably have some questions about them.

Are they worth the investment? How are they different from standard hoppers? What kind of maintenance do they need?

At Iron Bull Manufacturing, we’ve been working with low-profile hoppers for years, and we’ve got all your questions covered. In this guide, we’ll walk you through all the common low-profile hopper FAQs, helping you decide if they’re the right fit for your operation.

Let’s dig in.

Table of Contents

What Is a Low-Profile Hopper?

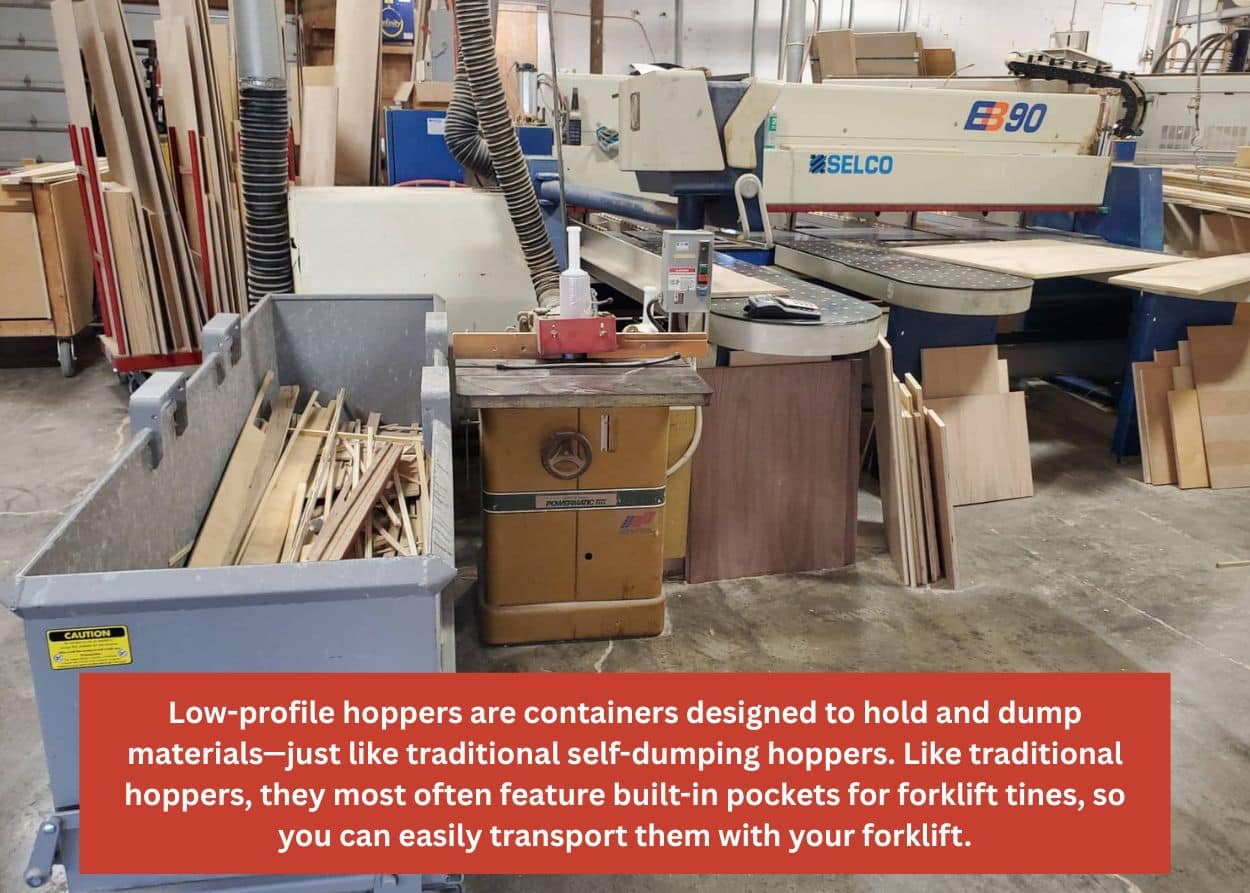

Low-profile hoppers are containers designed to hold and dump materials—just like traditional self-dumping hoppers. Like traditional hoppers, they most often feature built-in pockets for forklift tines, so you can easily transport them with your forklift.

The key difference is in their height.

The low-profile type is shorter, which makes it easier to fit under conveyors, workbenches, or tight machine setups. While standard hoppers may need more vertical clearance, low-profile models hug the ground.

Imagine trying to slide a large bin under a table. A standard hopper might get stuck, but a low-profile hopper fits like a glove.

Key differences at a glance:

- Lower height for clearance under equipment

- Wider base for balance and volume

- Ideal for tight spaces where standard hoppers won’t fit

If space is limited, these hoppers can help you maintain a smooth workflow without compromising load capacity.

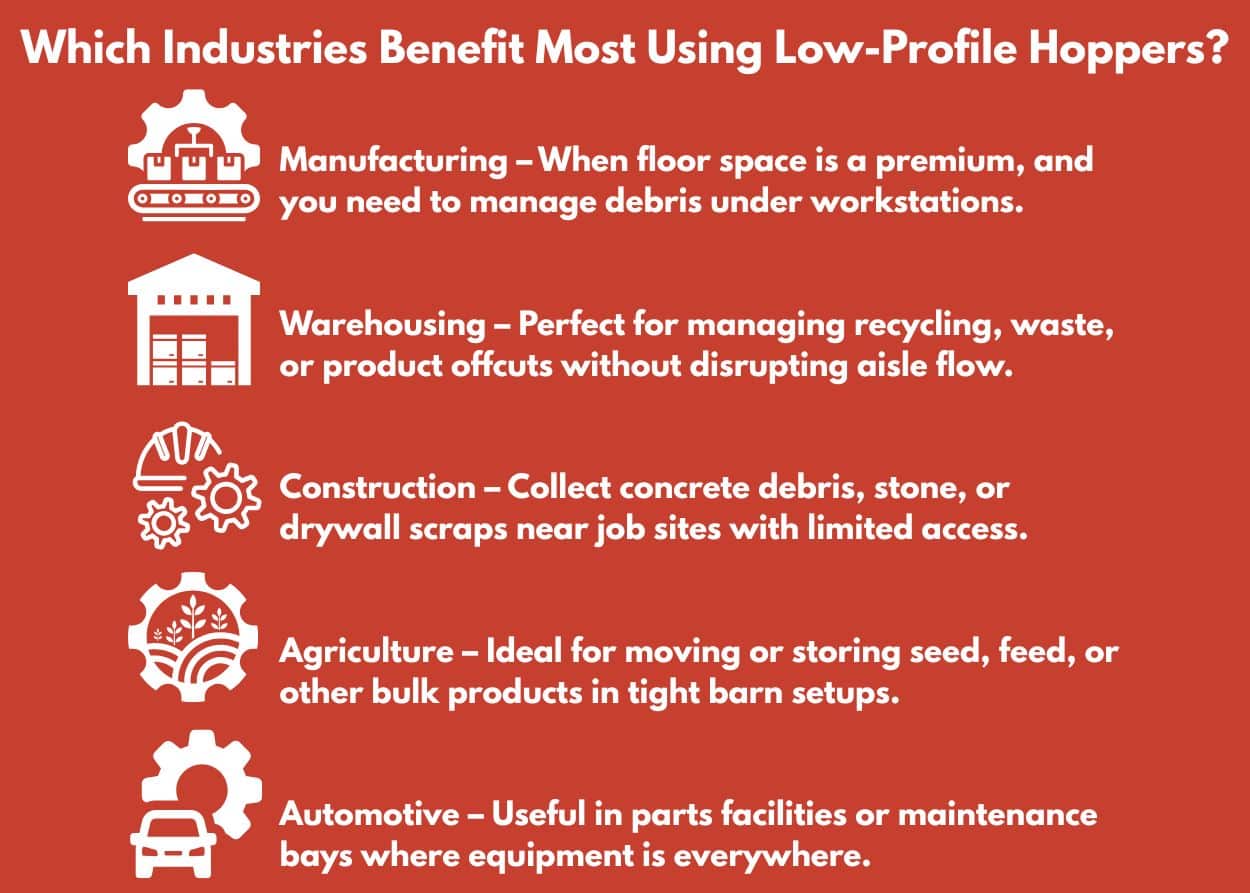

Which Industries Benefit Most from Using Low-profile Hoppers?

Low-profile hoppers aren’t just niche tools. They’re problem-solvers across many sectors. If your work involves collecting, storing, or transporting bulk materials—especially in limited space—these hoppers are your solution.

Here’s where they shine:

- Manufacturing – When floor space is a premium, and you need to manage debris under workstations.

- Warehousing – Perfect for managing recycling, waste, or product offcuts without disrupting aisle flow.

- Construction – Collect concrete debris, stone, or drywall scraps near job sites with limited access.

- Agriculture – Ideal for moving or storing seed, feed, or other bulk products in tight barn setups.

- Automotive – Useful in parts facilities or maintenance bays where equipment is everywhere.

If you need to maximize your space and improve your workflow, low-profile hoppers could be a great fit for you, whether you are a farmer, manufacturer, or construction worker.

Key Installation Considerations: Footprint, Mounting, and Integration

Before you bring in a trash hopper, it helps to think through your setup. A hopper is only helpful if it fits your workflow and your floor plan.

Here’s what you need to consider:

1. Footprint

Just because it’s “low-profile” doesn’t mean it’s small. The height is short, but the base can be wide, so some low-profile trash hoppers have large capacities.

- Measure the floor space where the hopper will sit.

- Make sure there’s enough room for forklift access if needed.

- Watch for obstacles like support beams, shelving, or conveyor legs.

2. Mounting and Support

Most low-profile trash hoppers are portable and come with forklift pockets. But if you need a permanent station:

- Check the surface—concrete pads are ideal.

- Consider bolting down if there’s frequent movement or vibration.

- Use safety chains or latches if tipping is a concern.

3. Integration With Your Workflow

Ask yourself:

- Does it need to slide under an existing chute?

- Will it dump directly into a waste bin or loader?

- Who’s operating it, and how often?

The right setup can prevent bottlenecks and reduce operator fatigue.

Pro tip: Talk to the crew who’ll use it. They’ll point out clearance issues you might overlook.

Maintenance Best Practices and How to Troubleshoot Common Issues

Like any piece of equipment, your hopper may need some care, and you’ll definitely want to train your crew to use it safely. But hoppers are built tough. In reality, they’ll last for years without too much babying.

Basic Maintenance Tips:

- Inspect welds and hinges. Look for stress cracks or rust.

- Grease moving parts if your model includes latches or tilt mechanisms.

- Check wheels or casters (if applicable) for smooth rolling.

Common Issues and Fixes:

- Sticking during dump: May be due to rust or misaligned hinge pins. A little lubricant and realignment usually solves it.

- Leaks: If you are using it for wet materials and it’s leaking, look for hairline cracks in the welds.

- Tip-over risk: Overloading unevenly or using on sloped surfaces can cause balance issues. Always load evenly.

Treat your hopper like you treat your tools. A quick check now and then saves major repairs later.

How to Choose the Right Material, Capacity, and Customization Options

Buying a hopper isn’t just about the size. It’s about the right combination of specs that fits your specific job.

Start with Material:

- Carbon steel: Tough, cost-effective, ideal for dry waste or bulk solids.

- Stainless steel: Best for food-grade or corrosive environments.

- Plastic/poly: Lightweight and non-reactive, but less durable under heavy use.

Capacity Matters:

Don’t go by cubic feet alone. Think in terms of what you’re actually moving. For instance, if you are moving heavy materials like metal scrap, go a little smaller to avoid overloading. If you’re moving lighter materials like sawdust or foam, larger capacities will be more efficient.

You should also consider the footprint. Larger capacities will likely have larger footprints.

Customization Options:

At Iron Bull, we often see customers request custom hopper add-ons like:

- Drain holes

- Lids or covers

- Casters for mobility

- Custom paint colors

- Crane eyes for lifting

Some operations even need a modified slope or opening for specific dumping needs. A custom design might be just the thing for your specific needs.

The best approach? Talk to your supplier. Describe your workflow, materials, and pinch points. A good vendor will guide you to a model that solves problems, rather than adding them.

Why Iron Bull?

Iron Bull Manufacturing has been building rugged, reliable equipment for years. Whether you’re dealing with scrap, powder, or heavy industrial waste, our hoppers are designed to take a beating—and keep working.

Our team understands real-world challenges: Tight corners. Heavy loads. Equipment that has to work every day.

That’s why we build our hoppers with extra-strength steel, reinforced seams, and smart designs that simplify your workflow.

When you invest in an Iron Bull hopper, you’re not just buying a product. You’re getting a solution that works as hard as your team does.

Final Thoughts

There’s no magic tool that fixes every material handling problem. But low-profile hoppers could fix some of yours!

If you’re struggling with space, tripping over bulky bins, or constantly stopping to clean up debris—this might be the missing piece in your workflow.

And when in doubt, reach out to a trusted brand like Iron Bull for guidance. We offer a variety of trash hoppers, including:

- Low profile hoppers

- Stretch hoppers

- Scrap metal hoppers

- Saw dust hoppers

- Construction hoppers

- Drop bottom hoppers

And much more!

You don’t have to settle for clunky, oversized, or poorly matched bins. Contact us today for more information!