Tractor ROPS FAQs

Table of Contents:

- What Is a ROPS?

- What Vehicles Have ROPS?

- Different Types of ROPS

- FOPS vs. ROPS

- Why Does a Tractor Roll?

- Are ROPS Mandatory?

- When Were ROPS Required on Tractors?

- OSHA Requirements

- Why Aren't ROPS Always Effective?

- What Are Foldable ROPS?

- When Should You Fasten Your Seat Belt?

- Can a ROPS be Repaired?

- Can You Weld on a ROPS?

- How Iron Bull Can Help

Farming is one of the oldest industries on the planet, and it is vital for everyone's health and well-being. If you’re a farmer, you know that technology will never make your job obsolete. However, farming has changed drastically over the last few hundred years, allowing for massive yields while also ushering in new safety considerations.

For example, while the invention of tractors allowed farmers to spend hours doing tasks that used to take days, they also led to a lot of terrible injuries and deaths related to rollover accidents. Today, it’s paramount that you equip your tractor with a roll-over protection structure (ROPS), both to comply with regulations and to keep you and your employees safe.

At Iron Bull, we specialize in robust ROPS and canopies that keep you safe in a rollover incident and shield you from uncomfortable and harmful UV rays. We’re sure you have many questions about ROPS, and we’d love to answer them!

Let’s get started.

Table of Contents

1. What Is a Roll-over Protection Structure (ROPS)?

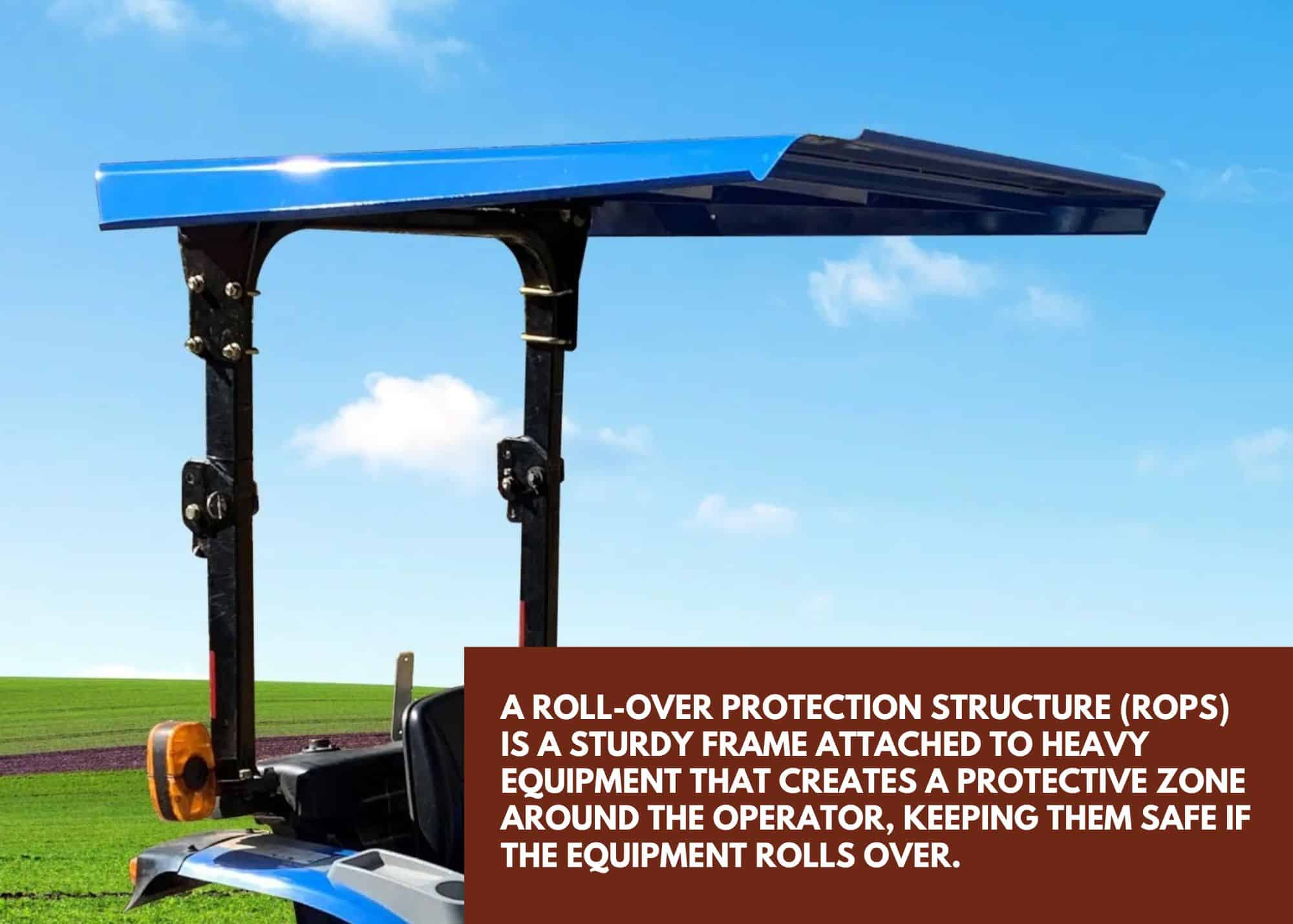

A Roll-over Protection Structure (ROPS) is a sturdy frame attached to heavy equipment that creates a protective zone around the operator, keeping them safe if the equipment rolls over.

The ROPS comes with a seat belt to keep the operator in the protective zone instead of being ejected and potentially injured.

Some equipment comes with a fully enclosed cab that functions as a ROPS. However, the term “ROPS” typically refers to a bar or frame attached to cabless equipment.

For more about ROPS, read our blog post about Tractor ROPS and Canopies: Everything you need to know.

2. What Types of Vehicles Usually Have Roll-over Protection?

You can find ROPS on a variety of vehicles used in industries where the risk of rollovers is high. These include tractors, construction equipment like bulldozers and backhoes, all-terrain vehicles (ATVs), utility task vehicles (UTVs), and skid steer loaders.

3. What Are The Different Types of ROPS?

The different types of ROPS include:

- Fixed ROPS, which are permanently attached to the equipment and provide continuous protection.

- Foldable or retractable ROPS, which can be folded down or retracted to allow machinery to operate in low-clearance areas.

- Two-post ROPS, the most common type of ROPS for tractors, includes two vertical posts with a horizontal crossbar on top. On a tractor, a two-post ROPS is mounted to the rear axle and sits just behind the operator.

- Four-post ROPS have vertical posts in front of and behind the operator, connected by crossbars and creating a cab-like space. Some vehicles, such as ATVs, sometimes have an ROPS with even more posts.

- Enclosed cab ROPS are cabs that protect the driver in the event of a rollover. Although cabs, such as enclosed tractor cabs, function as ROPS, they’re not usually referred to as such.

The type of ROPS you need will vary depending on your situation, but most tractors just need a simple fixed two-post ROPS.

4. What Is the Difference Between a FOPS and ROPS?

FOPS stands for “Falling Object Protective Structure” and provides an overhead screen, shield, or canopy to protect equipment operators from falling objects, such as rocks or debris. On the other hand, ROPS stands for “Roll-over Protective Structure” and protects the operator from serious injury in a rollover by creating a “safe zone” around the driver with a sturdy frame or cage.

Many pieces of equipment have both a FOPS and ROPS integrated into one structure.

5. What Causes a Tractor to Roll Over?

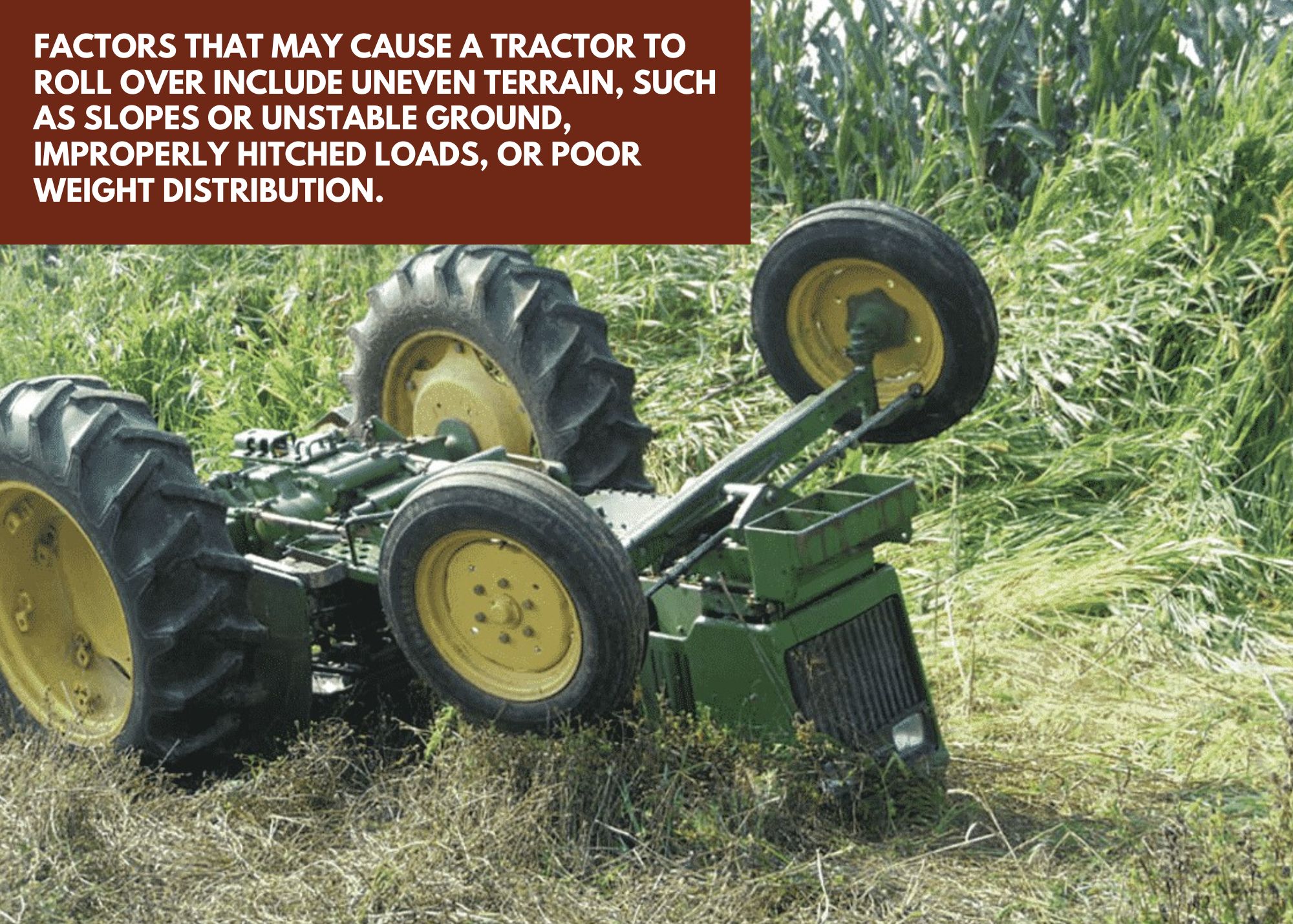

Factors that may cause a tractor to roll over include:

- Uneven terrain, such as slopes or unstable ground

- Sharp turns, especially at high speeds or with a raised loader

- Improperly hitched loads, which can destabilize the tractor and cause it to flip backward

- Excessive speed, reducing control and stability

- Poor weight distribution, such as carrying heavy loads too high or unevenly

With the proper preparation and training, equipment operators can avoid most rollovers and stay safe if one happens. For more information, read our blog post—Stay Safe on the Farm: Tractor Safety Precautions You Should Know.

6. Are ROPS Mandatory?

Laws and requirements about ROPS vary by country and industry. In the United States, OSHA requires ROPS on tractors used in agricultural and industrial settings for equipment manufactured after specific dates, such as 1976 for most new agricultural tractors. However, older equipment is often exempt unless retrofitted voluntarily.

7. When Were ROPS Required on Tractors?

Rollover Protective Structures (ROPS) became mandatory on tractors in the United States starting in 1976 for most new tractors sold for agricultural use. The Occupational Safety and Health Administration (OSHA) established this requirement to reduce the risk of fatalities and serious injuries caused by tractor rollovers, a leading cause of farm accidents. While older tractors were not required to have ROPS, many manufacturers and organizations encourage retrofitting them to enhance safety.

8. What Are the OSHA Requirements for ROPS?

OSHA mandates that ROPS must be installed on tractors and certain types of heavy machinery used in agriculture, construction, and other industries where rollover risks exist. Specifically, OSHA requires ROPS on all wheeled agricultural and industrial tractors manufactured after 1976 and used by employees.

The ROPS must meet performance and testing standards to ensure structural integrity during a rollover and must be accompanied by seatbelts to keep operators within the protective zone. Employers are responsible for ensuring compliance with these standards, and retrofitting older equipment with ROPS is strongly encouraged, though not always mandatory.

9. Why Is the ROPS System Not Always Effective in a Rollover Situation?

Although most people think of the ROPS as the rigid bar that creates a protective zone for the equipment operator, the seatbelt is a crucial system component. If the operator has not fastened their seatbelt, they can be ejected from the equipment in a rollover situation and severely injured or killed.

If the ROPS is damaged, improperly installed, or poorly maintained, it may be less effective in a rollover situation. And, of course, in an extreme rollover such as over a steep drop, the ROPS might not be enough to save the operator from severe injury.

However, as long as the ROPS is properly maintained and installed, and the operator is wearing a seatbelt and practicing common sense, the ROPS will work as intended and keep the operator safe.

10. What Are Foldable ROPS on a Tractor?

If you’re navigating your tractor under trees or through low doorways, a fixed ROPS might get in the way. When raised, a foldable ROPS functions like a regular fixed ROPS, but can be folded away to operate in places with low clearance.

But be careful, and ensure your foldable ROPS is securely locked in place during normal conditions!

11. When Should You Fasten Your Seat Belt on a Tractor?

The longer you farm, the more you’ll instinctively know what conditions are risky and what aren’t. For example, if you’re working on uneven or hilly terrain, your tractor has a higher risk of rolling over.

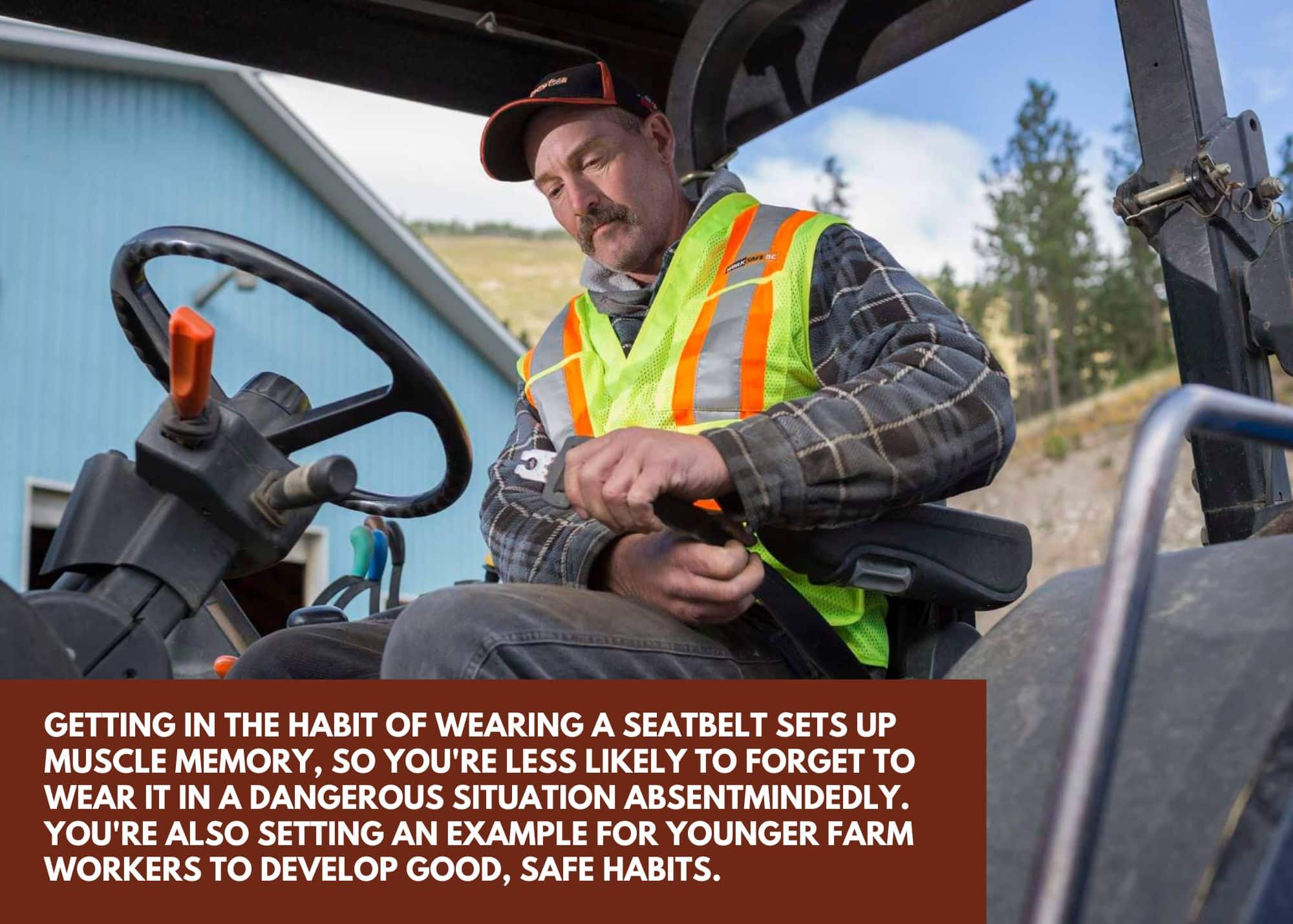

While you should absolutely wear your seatbelt in risky conditions, it’s best to get in the habit of wearing it all the time for the following reasons:

- You’re setting an example for younger farm workers who may not be as adept at assessing risk as you are

- If you get into the habit of not wearing a seatbelt, you’re more likely to absentmindedly forget even if you are in a dangerous situation

Rollover accidents are dangerous, traumatic for the victim and their family, and disruptive to a busy harvest, so safety habits like seatbelt wearing are in everyone’s best interest.

12. Can a ROPS be Repaired?

If your tractor rolls over or if the ROPS is damaged in some other way, the future effectiveness of the ROPS will be compromised.

Although some companies offer ROPS repair services, ensure the technicians are reputable and trustworthy and will repair the ROPS according to the manufacturer’s specifications and safety standards. After all, in the worst-case scenario, your life could be in their hands.

In many cases, replacing a damaged ROPS entirely is safer than attempting a repair.

13. Can You Weld on a ROPS?

In general, you should not weld on an ROPS. If not performed correctly, welding can weaken the integrity of the ROPS, potentially compromising its ability to protect the operator during a rollover.

If welding is necessary to repair or modify a ROPS, only entrust that task to a qualified professional experienced in welding safety-critical structures, who will follow the manufacturer’s guidelines and use the appropriate materials and techniques to maintain the frame’s strength.

How Iron Bull Can Help

If you’re looking for robust ROPS to protect you or your farm workers from harm, look no further than those we sell at Iron Bull Manufacturing!

We specialize in ROPS that come with a canopy to protect your operator from discomfort and harmful UV rays, and that match your tractor’s specific brand colors.

Are you curious about what our ROPS can do for you? Get a quote today!