Forklift Dumpsters: Everything you need to know [plus 4 ideal applications for them]

Have you ever heard the saying that “time is money”?

If you are a plant manager, or oversee the manufacturing floor, you know this saying is true without being told!

Every minute you or your employees spend doing tasks that don’t contribute to the success of the business you are hurting yourself.

In production and manufacturing plants, taking care of all the trash that gets created in the process of producing your products is a huge time waster. And of course, that wasted time equals wasted money.

It’s frustrating - but is there any way to address the problem?

At Iron Bull Manufacturing, we believe there is.

Today we want to help you address the issue of waste at your business so you can start saving time, money, and energy.

Ready to find out how you could do that? Let’s go!

4 Types Of Manufacturing Waste

Before we get started on how you can reduce waste, it’s critical to pinpoint where you are spending extra time dealing with your trash.

Here are the main areas that are problematic for many production plants:

Waste Of Transport

Let’s begin with a practical example that everyone has experienced at one time or another.

Suppose you come home from the store with 8 bags of groceries. If you take 2 bags each time, you’ll have to take four trips to the car and back.

Alternatively, if you can handle four each time, you’ll only have to take two trips to the car and back. You’ve effectively cut your time in half for carrying in the groceries.

The concept here is simple: moving products from one place to another takes time. The fewer trips you can take the better.

It adds no value to your products and takes money out of your pocket. In manufacturing, this waste is particularly expensive, as you need both vehicles and manpower to transport your goods.

To combat the waste of transport. consider the layout of your manufacturing plant. Take the shortest route to the dumpster and don't cart trash further than you need to. Beyond that, you should think about what machinery you are using and consider how you can better utilize it. In some cases, new machinery may be needed to reduce your waste of transport.

But before you spend money on a new technology or piece of equipment, make sure you do the hard, creative work of figuring out how to make what you already have work well.

Waste Of Motion

Wasted motion is an unnecessary movement by both man and machine.

It can be as noticeable as walking across the entire warehouse unnecessarily or as seemingly insignificant as rotating a tool for use after plucking it from a box. Other examples include:

- Sorting through a pile of tools to find the right one

- Reaching across a workbench to throw away trash

- Regularly walking back and forth to use a piece of equipment

As you can imagine, these motions cost you time and money and cause stress to employees and machines. The more streamlined your movements are the more productive you will be.

Waste Of Waiting

Most of us don’t love waiting in general - but it is especially frustrating in the workplace when you know precious minutes that could be used to make money are slipping by fruitlessly.

Unfortunately, downtime spent on waiting is more common than you might think.

Unbalanced processes are a major culprit of wasted wait time in your workflow.

If one process takes longer than the next then the operators will either stand there idly, or they will perform their tasks at slower speeds to fill up the time.

Here are a few examples:

- Waiting for a previous process to complete a batch of material prior to movement

- Waiting for a forklift to deliver a batch of components

- Waiting for trash to be dumped and the dumpster to be brought back

Again, every minute spent idly waiting is a minute that is costing you money.

Waste Of Space

Ask a facility manager to list the biggest challenges they face, and they almost unanimously include “space” in their top three, if not number one.

When we talk about “managing space” however, there are a lot of different ways to define “waste” and ways to create waste by poor utilization.

Here are a few ways to look at it:

- Building Selection – Choosing the right building is often the BIGGEST factor in space utilization.

- Layout – For whatever space you’ve already built or leased, the layout will impact not just your space utilization, but all your processes too.

- Racking and Equipment – Your choice of racking and the equipment you use to access it and use it will also matter.

- Processes – Your own processes can lead to massive wasting of space, and time, as well.

The bottom line is that you need to be stingy with your space. Every inch matters in your workflow.

Beyond that, overly crowded spaces can become hazardous for workers.

It’s completely worth your time to make sure you are maximizing the space in your manufacturing plant.

There are several other types of manufacturing waste that we will not cover in this article since they are not pertinent. However, if you want to learn more about them, make sure to read our blog: 7 Types Of Waste In Lean Manufacturing & How To Reduce Them.

How A Forklift Dumpster Helps You Minimize Waste

Once you’ve determined which type of waste is the biggest problem at your place of business it’s to move on and find a solution to your problem.

To be clear, there is no one silver bullet that can check all the waste problems you may be facing.

However, we want to introduce you to one piece of equipment that can help you reduce wasted transport, motion, wait time, and space.

The piece of equipment is called a forklift dumpster. Let’s find out how it works!

What Is A Forklift Dumpster?

Have you ever heard of a self-dumping hopper?

They are primarily used to collect trash and scrap - similar to a dumpster.

However, self-dumping hoppers are specifically designed to be easy to move, and easy to dump so you don’t have to waste time transporting trash.

If that’s not enough, you can buy self-dumping hoppers in a myriad of design options so you can get the scrap collection system that perfectly fits the needs of your business.

For example:

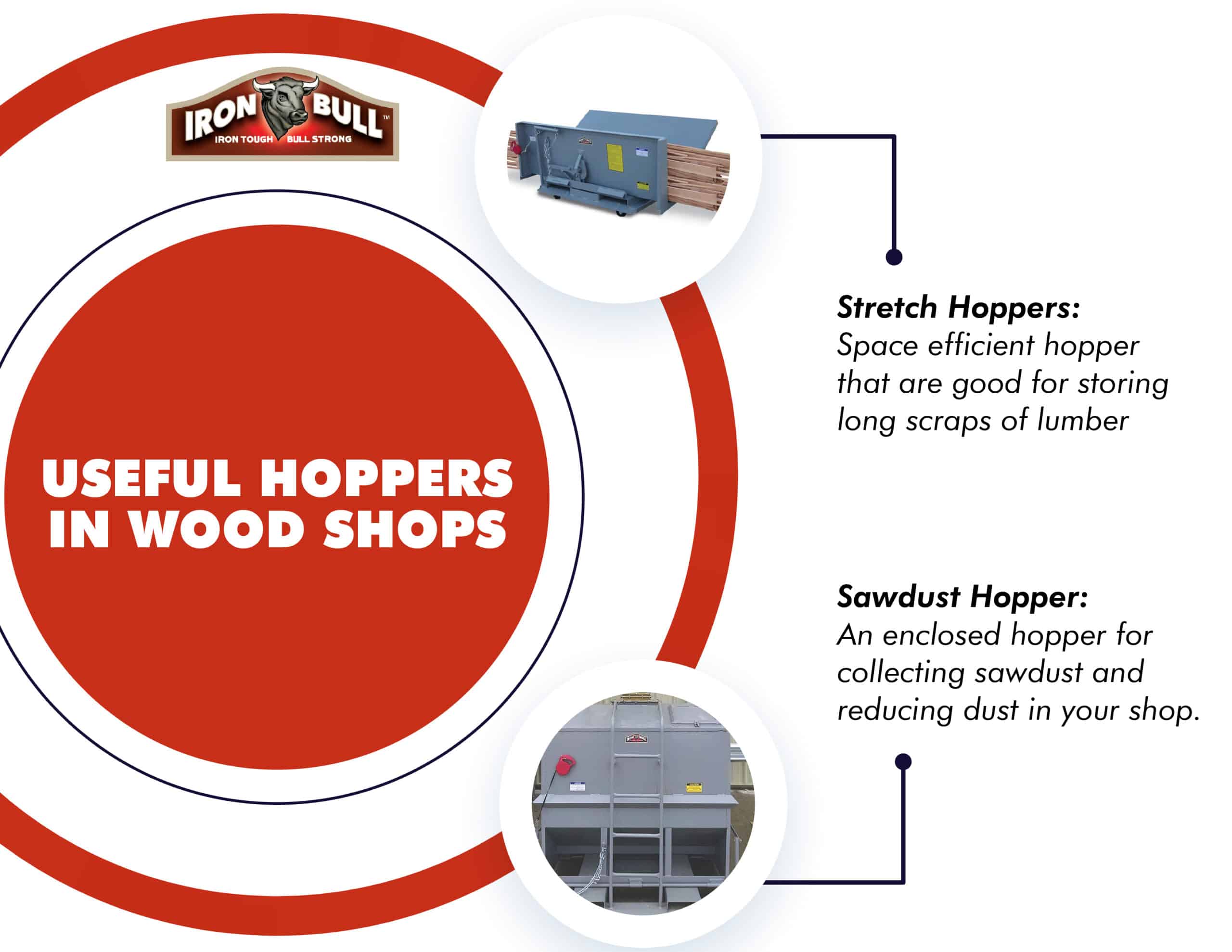

- A sawdust hopper can hook directly to a cyclone, virtually removing the transportation of sawdust in a shop.

- A low-profile hopper can fit under a workbench or anywhere else in a crowded workspace to save you space.

- A stretch hopper is perfect for collecting long scraps, or moving inventory items that are long.

A forklift dumpster is simply a specific kind of self-dumping hopper that can be transported with any vehicle that has forks.

This makes a ton of sense!

Whether you buy a drop bottom hopper or a construction hopper you need to have a simple way to move it. After all, easy moving and easy dumping is the primary feature of a self-dumping hopper.

What could be easier than driving up to a trash hopper with your forklift, sliding the forks into built-in fork pockets, taking the trash to a dumpster, and pulling a lever to dump your load of trash?

Not much, right?

With a self-dumping forklift hopper, that’s exactly what you get!

P.S. Do you want to learn more about running an amazing manufacturing business? Make sure to read our blog: 5 Lean Manufacturing Principles & 10 Tools You Need For Your Manufacturing Plant.

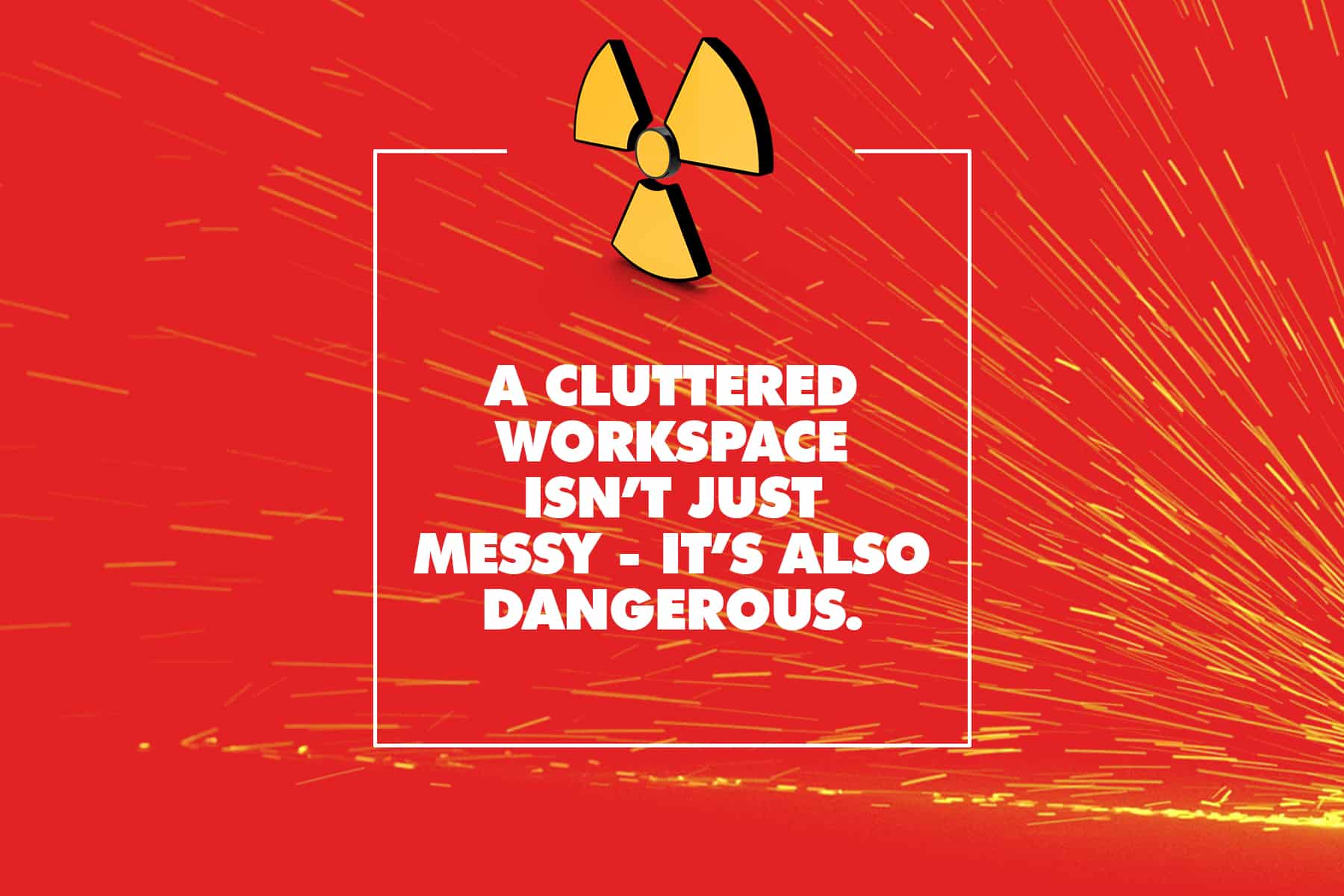

Benefits Of A Forklift Dumpster

We know what a forklift dumpster is - and we have a basic understanding of how they can help you save time and money.

But we understand that no one wants to make a hasty decision when it comes to investing business resources.

So, let’s take a closer look at how a forklift trash hopper can benefit your business!

Increase The Efficiency Of Your Business

As we’ve already mentioned, any manufacturing plant has a laser-like focus on increasing its efficiency. Every little thing matters!

It’s time to get down to business and take a practical look at how forklift dumpsters can boost efficiency for you business.

- Large loads of garbage can be thrown into a self-dumping hopper, loaded onto a forklift, and dumped, rather than small load after small load being taken out by employees.

- Employees have more time and energy to focus on their essential tasks instead of worrying about cleaning up or emptying the trash.

- Efficient storage of trash cuts down on clutter. This reduces wasted motion and minimizes frustration about junk laying everywhere.

- Streamline and simplify your workflow by using hoppers to load and unload materials - not just scraps.

Make Your Workspace Cleaner And Safer

What would happen if you had to jog 3 miles each time you wanted to empty the trash?

Most likely, the trash wouldn’t get taken out - you would ever want to! - and eventually, it would start to accumulate all over your house and property.

The result?

Your house would become unbearably stinky and you would get incredibly frustrated with all the clutter that keeps you from everyday activities. It’s not a stretch to say that you would find a way to get the trash emptied without needing to jog the 3 miles!

The same is true in a manufacturing plant or shop that doesn’t have a good way to get rid of scrap - except the stakes are even higher.

A cluttered workspace isn’t just messy - it’s also dangerous. Scraps of wood laying on the floor can trip people up, and exposed metal scraps are downright vicious! They could cause major lacerations. All it takes is one wrong move in a cluttered shop, and an accident could occur.

Sure, it's easy to assume that no accidents will occur in your manufacturing business.

But when they do, the results are scary.

An injured worker will be facing medical costs, recovery time, lost wages, emotional trauma, and will have to deal with the process of obtaining compensation – whether through workers’ compensation or a personal injury lawsuit, or both.

Accidents also present several costs to the employer including:

- Salary costs

- Productivity losses

- Retraining

- Compensation

- Repairs

- Medical and travel expenses

- Additional supervision

Take it from us: safety should always be a priority. And it's better to be safe than sorry!

Thankfully, forklift trash hoppers make scrap storage easy so you can keep your work area clean and safe.

Furthermore, they help you meet workplace safety guidelines required by The United States Department of Labor (OSHA). It’s a win-win!

Retain Happy Employees

Having happy employees is extremely important for the survival and performance of any organization. Happier employees work harder, work better together in teams, and are generally more productive. Every employer wants all that!

Of course, creating an environment in which your employees can thrive is a multifaceted process.

However, we can guarantee that when your employees feel safe and competent in their jobs they will be happier - and forklift hoppers help you check both those boxes.

The outcome is undeniable:

- Your employees will care more. Highly engaged employees are more productive and do better work.

- Happy employees are more likely to stay with your business for the long term. A lowered turnover means less time and money spent on hiring and training new employees as well as fewer breaks or slowdowns in productivity to induct them.

- When your employees feel fulfilled, they are literally healthier. Work-related mental disorders not only negatively affect the immune systems of individual employees but also bleed out the company with costs associated with the frequent or long periods away from work.

Ideal Uses For A Forklift Dumpster

Forklift dumpsters are incredibly useful - and help you become much more efficient in your work processes.

However, utilizing a self-dumping forklift hopper might not be the best option for taking care of your household trash or cleaning out the garage!

In fact, if you don’t have a forklift, or if your waste needs to be disposed of somewhere a forklift can’t go, a forklift dumpster may not be that helpful.

So, which types of businesses are best for a forklift hopper? Let’s find out!

Manufacturing Plants

Manufacturing plants are a perfect fit for forklift dumpsters on a number of levels:

First, manufacturing plants are often large buildings that have room to operate a forklift. On top of that, forklifts are commonly used for other tasks at manufacturing plants, which means you likely already have one.

Plus, manufacturing plants pump out a lot of trash, which means getting rid of waste efficiently is very important.

Here’s a true story about one manufacturing business that used self-dumping hoppers to give their business an edge:

In early 2014, a large RV manufacturer in Nappanee, Indiana, issued a challenge to Iron Bull.

“Build an 8-1/2 ft. wide self-dumping hopper for long scrap, mounted on casters, and made to fit a height flush or slightly lower than their table saws.”

Why?

The manager saw a way to eliminate a small but unnecessary time-and-motion step for workers.

He recognized it wasn’t necessary to pick up the scrap by hand to toss it up and over the side of the tall scrap container 6 feet away for every cut.

The result was a stretch hopper that allowed the RV manufacturer to save time, motion, and money.

And self-dumping hoppers aren’t just for RV manufacturing plants!

Whether you manufacture windows, mini barns, or automotive parts, a self-dumping hopper helps you haul, store, and efficiently dump products.

Wood And Furniture Shops

Working with wood is true artistry and a lot of fun. But it also creates a lot of scrap and sawdust.

If you own a wood or furniture shop you know exactly how quickly you can find yourself up to your neck in clutter!

Thankfully, a forklift dump hopper can help you deal with every kind of wood waste.

Do you have lots of long scraps of wood? Try a stretch hopper! They are space-efficient and good at storing large scraps. Beyond that, they are specifically designed to avoid “bridging” so you don’t waste any space in your hopper.

Maybe sawdust is a bigger issue in your shop. If so, you could try a sawdust hopper or a bottom dump hopper that drops trash out of the bottom of the hopper.

The drop bottom feature is especially useful with sawdust since it cuts down on dust, and allows for a specific dump location.

In fact, the benefits of a drop bottom hopper are numerous! Read our blog to learn more: Bottom Dump Trash hoppers: Styles, Uses, And Benefits.

Metal Scrap

Allowing pieces of metal trash to lay around is very dangerous. Metal waste is often sharp - easily deadly enough to gash a head or puncture a foot.

The less scrap metal you have cluttering your space, the better. And if you can avoid handling the metal by hand, that’s even more preferable.

Metal materials are also quite heavy, so having equipment to move them around is essential.

Thankfully, self-dumping hoppers help you to do both of those things.

Just make sure you choose a hopper built with extra thick steel if you are using it to store metal scraps and move metal materials. After all, whichever container stores metal is going to take quite a beating.

Metal CNC Machining

Metal CNC shops pose a unique challenge to storing and disposing of waste:

What can you do with the oil you use in your CNC milling, drilling, or grinding operation? Should you just put it in a dumpster with the rest of the scrap from your shop?

Unfortunately, that’s not an option.

Disposing of propane tanks, fuels, oils, and other flammable materials in a dumpster is a serious safety hazard. That’s why putting oil in a dumpster is illegal in most areas.

Thankfully, there are self-dumping hoppers that can help you solve this problem.

With a fluid reclaim hopper, you can store and transfer scarp without worrying about oil, water, or other liquids also being emptied into the hopper.

It's simple:

The fluid reclaim hopper allows you to quickly drain any liquid before you dump the hopper into a dumpster. You can get rid of your scrap without worrying about breaking any laws!

Frequently Asked Questions About Forklift Dumpsters

Maybe by now you are considering a forklift dumpster for your business.

However, we understand that each business is unique and has distinct needs. There’s a good chance you are asking a lot of questions in your mind about how a forklift hopper would work at your business.

We can’t guess all your questions - but we’ll do our best at answering some of them here.

And if you still have more questions, don’t hesitate to contact us at Iron Bull. We’re always happy to answer any questions you have!

Can Self-Dumping Forklift Hoppers Be Used In Off-Road Situations?

A forklift hopper may not be your best option for off-road or rough terrain situations.

However, the answer to this question is more dependent on your machine than the hopper itself. If you own an all-terrain forklift, then a hopper will be fine. If your forklifts are meant to stay in the shop, you may want to look elsewhere.

It may be worth looking into our skid steer quick attach option for trash hoppers. This allows you to take your trash anywhere a skid steer can go!

What Are The Dump Options On A Forklift Dumpster?

Our forklift dumpsters have a variety of dumping options:

- Standard: Hand lever located on the hopper.

- Optional: Dump-from-seat which is a nylon leash that extends and retracts as needed. It has a magnetic clipping kit for easy transfer to and from your forklift.

- Optional: Automatic push-and-dump has a latch that can be gently pushed against a dumpster and activates the dumping action.

We highly recommend one of the optional options to save time and increase dumping efficiency.

Do Pallet Jacks Work On A Forklift Dumpster?

If your shop floor is small, but you still want an efficient way to move scrap, you may consider a pallet jack over an actual forklift.

Thankfully, pallet jacks are almost always compatible with forklift hoppers.

The only time a pallet jack does not work is if casters are installed on the bottom of the trash hopper.

What Forklift Pocket Sizes Are Available?

Our hoppers come in two forklift pocket sizes:

- 2.5" pockets

- 3" pockets

Conclusion

Imagine reducing waste, lowering production costs, and increasing productivity.

You can do all three by utilizing a forklift dumpster in your place of business.

But don’t take our word for it! Our customers have experienced the difference firsthand:

“I have never regretted buying the Iron Bull hopper. It fits perfectly in the space we need it in. It was a worthwhile investment!”

If you aren’t sure what kind of hopper would work best in your situation, that’s completely fine. That’s why Iron Bull is here. We’d love to apply our knowledge to your unique situation and help you find the best fix.

Whether it is our self-dumping hoppers, bottom dump hoppers, or a specialty hopper that we make specifically for your shop, we continue to help our clients win with excellent processes, products, and customer service!

We also provide a variety of tractor shade canopies, including:

- John Deere ROPS and tractor canopies

- International ROPS and tractor canopies

- Oliver tractor canopies and support frames

- Massey-Ferguson tractor canopies and support frames

- Ford tractor canopies and support frames

In whatever we do, we guarantee:

- Unparalleled customer service

- Quick response and shipping

- Strong and durable hoppers

Contact us today to learn more. We look forward to hearing from you!